New automation concepts with OPC Unified Architecture

With the introduction of the platform-independent OPC Unified Architecture (OPC UA), OPC technology has started to conquer new application areas, such as embedded systems or the IT world. Recently, the new technology has established itself in areas where OPC was hardly seen before, e.g. device parameterization. The reason for this breadth of application is that the OPC UA technology offers extended features when compared to Classic OPC. OPC UA's platform independence and, in particular, its scalability opens up many possibilities for new and efficient automation concepts.

Standardized communication

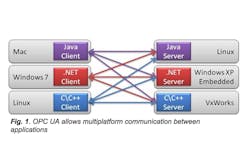

OPC UA facilitates the secure, reliable, and manufacturer-independent transport of raw data and pre-processed information from the factory floor to the production planning or ERP system. The desired information is provided to any authorized application and person, anytime and anywhere. This functionality is independent of the manufacturer that created the applications, the programming language they were developed in, and the operating system they run on. OPC UA is no longer DCOM based, but uses a service-oriented architecture (SOA). This makes OPC UA easy to port. Today, OPC UA builds a bridge between the enterprise level with Unix systems and embedded automation components running different versions of Windows and non-Windows operating systems (Fig. 1).

OPC UA provides a set of features that allows the implementation of new concepts for secure and robust plant automation. They include:

• Standardized communication over the Internet and across firewalls:

OPC UA uses a dedicated UA Binary protocol for data exchange that is based on TCP; Web services and HTTP are also supported. Only one port needs to be opened in a firewall – that's enough. Integrated security mechanisms guarantee secure Internet communication.

• Protection against unauthorized data access:

The sophisticated security concept provided by OPC UA technology ensures efficient protection against unauthorized access, sabotage, and faults caused by negligent use. OPC UA security is based on global standards developed by the World Wide Web consortium. It offers various possibilities to identify applications, authenticate users and protect against unauthorized access, as well as sign messages and encrypt the payload transferred.

• Data security and reliability:

The communication standard defines a robust architecture with reliable communication mechanisms, configurable timeouts, automatic fault detection, and recovery mechanisms. The communication link between a OPC UA client and server can be monitored by both the client and the server. If a connection is temporarily interrupted, the data can be buffered in the server. In security-critical areas, OPC UA defines an additional redundancy concept that can be used for devices, servers and clients.

• Platform independence and scalability:

Using service-oriented base technologies ensures that OPC UA is platform independent and opens up many possibilities for new and cost-effective automation concepts. Embedded field devices, process control systems, PLCs, gateways, or operator panels are developed using lean OPC UA server implementations that have been ported directly to operating systems including embedded Linux, VxWorks, QNX, RTOS, and many more.

• Simplification by unification:

OPC UA defines an integrated address space and an information model that maps process data, alarms, historical data, and program invocations. In this way, even complex processes can be fully described with OPC UA. While classic OPC requires three different OPC servers – DA, AE and HDA – with different semantics to acquire, for example, the current value of a temperature sensor, the event of excess temperature, and the historical average temperature, OPC UA needs only one component. This helps to reduce configuration and engineering times.

• High performance:

OPC UA is based on a binary protocol that is TCP-based. This very efficient protocol allows for a fast data exchange that will meet the high-performance requirements of most applications. The actual binary protocol implementation is available through the OPC Foundation and serves as the basis for all OPC UA servers and clients.

• New application possibilities:

The wide breadth of the OPC UA technology allows implementing new vertical integration concepts. By cascading OPC UA components, information can be transported securely and reliably from the factory floor all the way up to the production planning or ERP system (Fig. 2). For this purpose, OPC UA enabled client and server components at the automation level connect embedded UA servers at the field level with OPC UA clients integrated in ERP systems at the enterprise level. The individual OPC UA components can be geographically distributed and separated from each other by firewalls without problems.

Developing OPC UA based concepts

Many automation component vendors already offer OPC UA clients or servers for their PLCs, process control systems, field devices, or operator panels. An efficient and cost-effective way to build OPC UA components is to rely on conformant OPC toolkits, such as the OPC Toolbox UA (Fig. 3) from Softing [1]. This software allows the quick and easy development of OPC UA clients and servers for Windows, Linux, VxWorks and other embedded operating systems. OPC UA specific functionality for creating, browsing, and managing an OPC UA address space; for creating, deleting, reading, and writing OPC UA objects; for event handling, method calls, and much more has been fully implemented in the compact OPC Toolbox UA.

With the toolbox, developers can save several months of time and reduce the time-to-market for their products.

Conclusion

The future IEC communication standard OPC UA provides features that offer new possibilities of embedding an internationally standardized communication interface in disparate systems ranging from PLCs, process control systems, drives, gateways and operator panels to MES or ERP systems. The result is savings in installation, setup, commissioning, maintenance and operation. Communication structures can be simplified and vertical integration concepts consistently implemented. Toolkits like the OPC Toolbox UA allow the cost-effective and efficient implementation of OPC UA components under Windows and in embedded systems.