OPC UA for Performance Excellence: Control, Safety, People and Assets

In Session Two of the OPC Foundation workshop, “Transforming Manufacturing with OPC UA: From Embedded to the Enterprise,” held during last month’s ARC Forum, we heard from six industry experts on how OPC UA solves integration challenges at the higher levels of the organization, from process automation to the manufacturing execution (MES) and enterprise resource planning (ERP) systems.

John Krajewski, senior product manager HMI/Supervisory with Invensys, discussed OPC UA as a key enabler for performance excellence in control, safety, people and assets. In its ArchestrA System Platform, Invensys deploys OPC UA servers and clients to communicate among “galaxy” control systems linked to many thousands of I/O. Its Trident triple-redundant safety system has an OPC UA-based communications interface module, while other systems use OPC UA to trigger workflows and in process simulation models that improve asset performance.

Going green with OPC UA

A unique water reclamation project, providing up to 50 million gallons of reclaimed water per day, proved OPC UA to be a critical component of the City of Orlando’s environmental mission. Representatives from the City of Orlando Water Reclamation Project supported Tony Paine, president of Kepware, in his discussion of how OPC UA was used to interconnect reclaim water distribution systems between the City of Orlando and Orange County. “There were four pumping stations, all competing to put water into the system at the same time,” explained Paine. “They needed to manage the water pressure among the stations to effectively generate water into the delivery systems.”

A physical connection already existed between the city and county networks, but the new solution required a firewall-friendly, cross-domain communications technology that interoperated with the existing OPC Classic-enabled supervisory and control systems. The City of Orlando team chose Kepware’s KEPServerEx platform with OPC UA to provide secure, bi-directional data access between the different SCADA systems. As an added benefit, operators now have the appropriate data to make informed operational and maintenance decisions, including pump status, valve positions, flows, tank levels and pressure from each pump station.

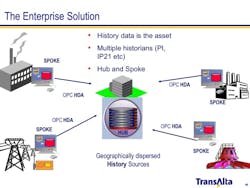

Global power generator TransAlta needed a vendor-neutral architecture to communicate among multiple facilities spread over four geographies, outlined Darek Kominek of MatrikonOPC, in his presentation. TransAlta, which is North America's largest non-regulated power generation and wholesale marketing company, operates 51 power plants in Australia, Canada, Mexico and the U.S., which generate power using coal-fired, gas-fired, hydro, geothermal and wind technologies. The company has a strong focus on operating asset efficiency to deliver reliable, low-cost power to its customers. There was a significant data delivery issue at the plant level. With 51 plants (and counting) comprising dozens of different architectures, it was difficult to provide the data necessary to make key real-time decisions.

TransAlta partnered with MatrikonOPC to build an operational excellence solution from the ground up, focusing on an OPC architecture and implementing Op Ex and specific initiatives on top of it, such as supply chain, reliability, workforce automation and knowledge management. The enterprise solution leveraged a hub-and-spoke architecture with geographically dispersed historians communicating via OPC. One of the primary business benefits is a data foundation that enables monitoring of key operating metrics by headquarter-based executives.

In all manufacturing applications, security is a mounting concern—but companies can do more to protect themselves, said Greg Hale, editor and founder of ISSSource, in his presentation, “OPC UA and Security.” According to ISSSource, top-tier companies are 2.5 times less likely to experience a major cyber attack than bottom-tier companies, and 3.5 times less likely to experience downtime. How do you become a top-tier player? Said Hale, “Take a long-term view of security, partner with companies competent in automation security, design security solutions that fit the requirements, and most importantly, be vigilant.”

Bridging the gap between real-time and business

The final two speakers of the workshop addressed how OPC UA is a key technology for linking real-time data systems to the transaction-based enterprise systems. Dennis Brandl, chief consultant for BR&L Consulting, is a noted expert in manufacturing execution solutions (MES) and the ISA S95 Enterprise/Control System Integration standard. His perspective on the developing OPC UA/95 specification is that it will serve as a bridge between the slow speed and occasional access requirements of corporate systems and the high-speed requirements of manufacturing operation management (MOM) systems.

“The B2MML [business to manufacturing mark-up language] standard provides a format for the information, but is designed for loosely coupled asynchronous processes, with transaction times measured in seconds,” said Brandl. “OPC-UA/95 will provide the high speed, tightly coupled response needs of MOM systems.”

With an interesting look into the future, Reiner Bildmayer, senior process architect for SAP Research, SAP AG, outlined the Future Factory Initiative, part of SAP Research’s Living Lab in Dresden, Germany. Manufacturing represents 21 percent of Europe’s GDP and 20 percent of its employment (30 million jobs); as such, the European Union has invested 8 million Euro (about $10.5 million) in the SAP Research project to develop PLANTCockpit, a production logistics and sustainability platform.

“PLANTCockpit is a layer above production control systems,” said Bildmayer. “It enables production supervisors, foremen, and line managers to make well-informed decisions for optimizing plant processes.” Bildmayer predicted that today’s manufacturing companies cannot be supported by ERP systems from three decades ago. “The next-generation ERP will be a collaborative enterprise management system, with OPC UA a perfect fit.” Among other megatrends for Manufacturing 2.0, Bildmayer cited a cloud-based business environment for collaboration, mobility, connectivity and intelligence.

See the previous article in this issue for an overview of Part 1: “Transforming Manufacturing with OPC UA: From Embedded to the Enterprise.”

Download an ARC Insight article on the workshop.

Visit OPC Foundation web site for more information on OPC UA.