Much has been written on the topic of manufacturing execution systems (MESs). Most articles, however, tend to focus on the pre-implementation steps: determining the need for MES software based on significant business drivers, justifying the investment, and selecting the specific applications and vendors, etc.. Here, however, we’ll look into the best practices for actually getting the software installed and working, so your company can reap the benefits of MES (also known as manufacturing operations management, or MOM) as quickly as possible.

The first step in any successful MES implementation is determining clear governance for the project.

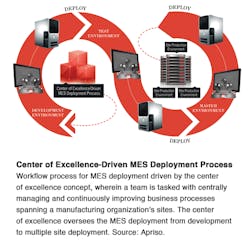

Deliberate thought should be given to how manufacturing processes will be governed throughout the entire information technology (IT) ecosystem of the supply chain, says Darren Riley, business solution manager for Apriso (a manufacturing software supplier based in Long Beach, Calif.). “Governance topics should include who has authority to change a process, and how will that change be tested, implemented and measured across the entire application infrastructure to ultimately determine operational agility,” he says.

Having a clear governance plan in hand requires the input and involvement of all stakeholders, even if some of those stakeholders will not be directly involved in the implementation process.To establish this governance process correctly, you have to look beyond IT and production and into quality, validation, operations, maintenance and executive management.

“They all need to be in the MES kickoff meeting and involved throughout the process,” says Bob Honor, vice president of Information Software, Rockwell Automation, Milwaukee, Wis. “There’s a change management process involved with any MES implementation and it’s most successfully managed when all involved are a part of the process right from the start.

>> Click here to read about MES and IT infrastructure challenges.

Some of these groups are left out because they’re not needed at the implementation stage, but that’s a mistake says Honor. They should all be there to ensure buy-in, use and success of the system by way of process improvements and cost savings as well as the other associated business benefits of MES.

“I’ve seen [MES] projects go off the rails without clear governance,” adds John Southcott, co-CEO of Brock Solutions (a systems integrator based in Irving, Texas). “MES implementation should be governed like any other major software installation. The chief information officer and vice president of manufacturing need to be in lock step and measured in the same way. Governance is where the project should start and it’s exactly where it will break down if not instituted.”

Implementation design

As with any operations-critical software implementation project, opinions on which specific steps to follow vary widely. In general, they tend to follow classic engineering project planning requirements involving design, configuration, testing, deployment, and lifecycle. As a result, vendors, system integrators and experienced end-users alike, cite several steps in common. Those steps are:

- Develop detailed MES system user requirements followed by a gap analysis for both the control system(s) layer and enterprise resource planning (ERP) layer.

- Publish a realistic schedule for implementation and testing.

- Conduct a risk assessment for the definition, design, development and deployment phases.

- Anticipate that an off-the-shelf software application will require significant adjustments for development of your operation-specific specifications, programming and testing.

- Define the integration points between the various layers that comprise your enterprise architecture. “The E in MES stands for execution and the P in ERP stands for planning. The ERP should be telling the MES what to make. The MES system should be able to tell what was made and where it went,” says Southcott. “Those systems need to be linked from a production process point of view.” With that issue addressed, the question becomes how often does the ERP need to be updated and how will handshakes between the systems occur.

- Integrate the MES software with other production control systems.

To smooth the implementation process, Riley says he has recently begun applying agile development methodologies to the process of architecting how the implementation will proceed. By using an iterative and incremental approach with smaller ‘chunks’ of functionality addressed by the governance team, the miscommunications and inability to correctly identify necessary scope criterion can be minimized quickly.

>> How long does it take to recoup your MES investment? Click here to read more.

Roads not taken

Even in a well-thought-out MES implementation, some of most critical steps in the process are often overlooked, forgotten or completely avoided.

Eight of the most common missteps are:

- Not ensuring that MES requirements are tied to specific business drivers.

- In the design phase, when getting into the details of master data ownership, interface points to the control systems, etc., steps get skipped when decisions are made to save on time or money or both, says Jon Miller, director global project delivery, Invensys Operations Management, Lake Forest, Calif. “By doing so, you risk scope creep, misaligned expectations, missing requirements, missing adherence to the schedule and budget, as well as missing the connect with the business requirements.”

- “User requirements often lack clarity or are not detailed enough, which means that development efforts cannot be properly estimated,” says Rob Gellings, Maverick Technologies (a systems integrator based in Columbia, Ill). “Also, modifications related to additional instrumentation, programming changes, etc., that are required for connection to the control system layer are often underestimated.”

- Risk assessments. These should be conducted at the definition, design, development and deployment phases.

- Design reviews. Be sure to take into account what you learn along the way, as that may alter the plan originally developed before the implementation began.

- Not establishing a current state-of-operations with which to compare the newly installed MES. If this step is not taken at the beginning, “you can’t figure out the exact benefit at the end of installation,” says Jeff Nuse, senior product manager, MES, Invensys Operations Management.

- Following the plan. “With a big software implementation like MES, you’re looking at doing everything from A to Z, but as you implement the system, people have to realize you can’t do A then do D then do B,” says Nuse.

- Testing. Just because it’s installed and all the outlined steps were followed, that doesn’t guarantee the system will operate at 100 percent of expectations. Verification tests are critical before completely switching over to the new MES system.

System check

Before making the MES implementation official and flipping the switch for its full application in the production process, two types of acceptance testing should be conducted. These tests are Factory Acceptance Testing (FAT) and System Acceptance Testing (SAT). Most everyone—vendors and system integrators alike—strongly recommend conducting both of these test procedures.

The principal difference between FAT and SAT, according to Miller, is that FAT is performed with simulation or test data. “SAT is done as you’re preparing to go live and you’re running the test on actual production environment using real interfaces,” he says. “This should test all integration points from control to MES.”

“A key deliverable for the FAT and SAT process is completing the pre-approved test plan that includes what-if scenarios and regression testing in addition to testing functionality per user requirement specifications,” adds Gellings.

With regard to user requirement specifications, Gellings says that a requirements traceability matrix is useful to confirm that functionality related to user requirements is ultimately tested and deployed.

>> Can ERP replace MES? Click here to read more.

Proper staging of the FAT and SAT process by the system integrator will expedite the discovery of system issues and confirm usability of the MES software as implemented.

Once the FAT and SAT process are completed, Riley recommends that an overall performance review and analysis be conducted once the site goes live with the MES, “to ensure the system and the workforce culture operates as a whole at the level first envisioned.”

Riley’s point about the workforce culture issue is critical and cannot be overlooked.

“I have seen many cases where new applications and processes are installed, but plant operations still maintains old Excel sheet programs,” says Southcott.

To address this, Gellings recommends the use of robust user manuals, either online or hard copy, or extensive help files embedded in the system along with in-depth training to aid in the adoption of the new system.

What about the hardware?

Given that any MES application is dependent on the data is gets from the automation hardware on the production line, no MES implementation should proceed without an early stage assessment of the state of your production equipment that will be delivering data to the system.

“I call it automation readiness,” says Honor. “This assessment of the hardware/automation layer should be part of initial project review. In process and complex assembly operations, there is a lot of data in controllers that you need to track in production. So assessing the readiness of various pieces of equipment to be able to communicate to the MES system is key. This will serve to reduce the integration timeline.”

Fixing these issues usually involves a CPU upgrade or a firmware upgrade on the controller. Any investment here pays off in orders of magnitude in reducing implementation costs.

“Any MES system that is not capable of effectively connecting to a heterogeneous automation environment might not be a smart choice,” says Riley. He clarified this statement by saying that operations should be managed holistically with all processes standardized, regardless of location or equipment installed.

“The concept of having operational agility is now triggering a movement of ‘product-centric logic’ to support operations from the automation layer into MES software,” Riley adds.

Of course, plant floor hardware is not the only hardware that matters with an MES implementation when it comes to managing the data that the system depends on to operate correctly. There are also the IT hardware issues to consider.

It’s important to follow the software manufacturer’s advice about keeping a certain amount of data on the production system, but then archiving that data on a rolling basis to a reporting system where it can be accessed easily but does not bog down the production system.

“We always stress this point, but its not always followed as closely as it should be,” says Miller. “MES systems generate a huge amount of data because of the level of granularity at which they track production and their real-time operation. Without good database management and equipment, it’s not unusual to see a successful implementation start to have problems a year or so after implementation because the health of database was not maintained.”

>> Click here to read how Chivas Brothers is using software to capture and disseminate the expertise of their star operators. Visit bit.ly/caseapp005

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: