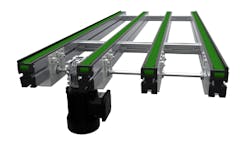

Multi-Strand Pallet Handling Conveyor System

Glide-Line offers the most versatile multi-strand panel and pallet-handling conveyor solution available for PV panel handling technology that takes in consideration the demands of the solar industry. Wafer-based solar module manufacturing processes are extremely sensitive, demanding smooth vibration-free, clean and efficient transport.

Glide-Line’s proven transfer technology is ideal for high volume production projects and top quality performance. Glide-Line’s understands the concern of sensitivity for transporting the modules. “Stress can cause almost invisible microcracks in photovoltaic modules which once installed lead to a loss of power,” says Kevin Mauger, Glide-Line’s President. “Glide-Line tests every system to ensure low friction and in the evaluation process holds to a high standard ensuring compatibility for ISO and ESD environments.” The Multi-Strand Pallet Handling Conveyor System is the foundation of the Glide-Line System. The Conveyor is designed to transport PV panels through the assembly process. Transport conveyors offer multiple connection alternatives to suit a variety of assembly system requirements and are available with multiple power input options as well, including 24 VDC motors. Sizes of the systems range from a minimum width of 140mm to as many tracks as required.

Benefits include

- Optional patent pending centerline adjustable conveyor

- Configurable models for SolidWorks use

- All Glide-Line systems utilize T5 timing belts with steel tension members for positive drive, durability and reduced maintenance

- All maintenance operations including belt changes can be performed from the top eliminating the need to disassemble or remove ancillary equipment.

- Drive shaft 14mm, End roller 28mm, Drive pulley 5mm pitch, 40 tooth

- B14 flange motor – 218ft / minute

- 24VDC direct drive option for ultra-quiet maintenance free operation, absence of gearbox and connecting shafts offer ultimate design flexibility

- All rolling elements are precision ball bearing supported for long ultra-quiet, high-load maintenance free operation

- Multiple, mounting drive configurations available AC single, 3 phase options, as well as 24VDC options

>> For more information on this product, click here