Power Factor and Its Impact on Energy Use

Most discussions on manufacturing energy efficiency focus on identifying easy-to-find-and-fix energy wasters such as compressed air leaks, inefficient lighting, equipment that is always left on when it doesn’t need to be, etc. But as those energy wasters are addressed, the next step is learning the power factor of your manufacturing facility.

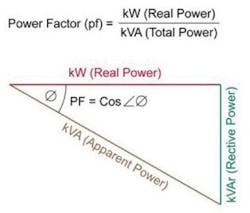

Power factor is the ratio of real power to the apparent power flowing to the load from the source. This is an important piece of knowledge for manufacturers because a low power factor raises your plant or factory’s power bill.

Following is a brief outline of what power factor is, how to calculate it, and how to address it. For the record, this information was supplied to me by CAS Data Loggers, a provider of data logging equipment; its Accsense Electrocorder EC-7VAR Power Data Logger can be used to help identify power factor issues.

Measuring the Power Factor

Power factor (PF) is measured between 0 and 1.0 (usually given as a percentage, with 100 percent or 1.0 being unity). If your facility’s PF is below a certain level (typically 95-96 percent), your utility will charge a reactive power fee. This is because a low PF represents an inefficient load source that is drawing reactive (i.e. non-working) power that the utility has to make up for.

The best use of power in an AC circuit is when the voltage and current are in alignment. However, much of your electrical equipment is probably delaying as it draws current, meaning that the current and voltage are misaligned and causing it to draw more current to operate.

An AC circuit’s power factor is calculated using three aspects of its electrical power as they relate to one another (see the image associated with this article):

* Real power—Power used to run equipment, expressed in kW.

* Reactive power—Power which does not produce work, expressed in kVAr. As reactive power use increases, your electric system loses more energy, hence the reactive power fee.

* Apparent power—The combination of real power and reactive power, expressed in kVA.

The bottom line is that your PF percentage shows you how much of the total current you are drawing is being used to do real work. For example, a PF of 80 percent means that 20 percent of the current flowing into your facility is non-working power.

Raising Your Power Factor

There are several power factor correction techniques that can be applied. One of the more common ways to do this is installing correction equipment to reduce or remove these costs. But there are a few simple methods you can use to raise your PF without buying these expensive devices, such as:

Check your existing equipment to see if any pieces are operating above the voltage it’s been rated for. You can also cut back on how often your plant is running motors with a light load and avoid running idling motors for extended periods.

Linear loads with a low power factor, such as induction motors, can be corrected using a passive network of capacitors or inductors. For example, you can offset the inductive effect of motor loads by using locally connected capacitors. If a load has a capacitive value, connect inductors (also known as reactors) to correct the power factor.

Use an automatic power factor correction unit, consisting of a number of capacitors that are switched by means of contactors. These contactors are controlled by a regulator that measures power factor in an electrical network. Depending on the load and power factor of the network, the power factor controller will switch the necessary blocks of capacitors in steps to ensure that the power factor stays above a selected value.

For power factor correction of high-voltage power systems or large, fluctuating industrial loads, power electronic devices such as the Static VAR (volt ampere reactive) compensator or STATCOM (static synchronous compensator) are increasingly being used. These systems are able to compensate for the sudden changes of power factor more rapidly than contactor-switched capacitor banks.

Power Factor Correction Benefits

Beyond lowering your facility’s electricity bills and avoiding reactive power fees, increasing your facility’s power factor also reduces carbon emissions, reduces I2R losses in transformers and electrical distribution equipment, and reduces heat in cables, switchgear, transformers and alternators which can prolong the lifespan of equipment.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: