Select your vacuum conveyor from one of 30,000 standard configurations for quick delivery

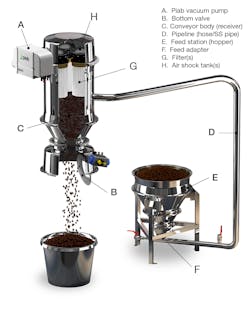

Piab, a leading supplier of industrial vacuum technology, introduces piFLOWp. It is the new Premium conveyor line from Piab, meeting the high demand from the Food and Pharma industries. With its proven design for robustness and cleanability, Piab conveyors are regarded as the leading alternative for vacuum conveying worldwide. With the launch of piFLOWp we will take yet another step in terms of flexibility, dynamic documentation and lead time.

The vacuum generated by piFLOWp is produced in the most energy efficient way, namely through utilizing COAX cartridges. The COAX cartridges are smaller, more efficient and more reliable than conventional ejectors, which allows for the design of a flexible, modular and efficient vacuum system. A vacuum system based on COAX technology can provide your customer with three times more vacuum flow than conventional systems, while reducing energy consumption.

piFLOWp is designed according to USDA and GMP guidelines. All materials are FDA approved and all configurations can be delivered with an ATEX Dust certificate.

The new piFLOWp design makes it possible to tailor your conveyor and at the same time have instant access to technical data, drawings and CAD files. This makes the integration work much easier as you can change your configuration parameters online and see if the conveyor system fits into your application, instead of waiting weeks for a new drawing from the supplier. Our goal is to cut down project lead time for our customers without compromising flexibility.

piFLOWp and COAX are registered trademarks.

>> For more information, click here