Plant-to-Enterprise Integration

Getting disparate systems—from the plant to the business level—to automatically share data effectively for improved business intelligence, visualization and decision making has been a long-sought-after industry goal. That goal is now within reach with the release of the Wonderware Enterprise Integrator—a commercial off-the-shelf software integration application that provides data exchange and automatic data synchronization between two or more business and/or plant systems.

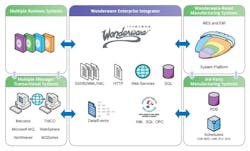

The system integration capabilities of Wonderware Enterprise Integrator include handling of XML messages, flat files, and database queries beyond Wonderware applications, allowing for the integration of diverse plant applications with ERP or other business and enterprise-level systems in a single package. Typical integration scenarios for Wonderware Enterprise Integrator include connecting business systems with Wonderware MES Software, Wonderware InBatch, Wonderware Intelligence, and Wonderware System Platform.

By linking Wonderware Software or Wonderware System Platform-based applications to third party software applications such as Enterprise Resource Planning (ERP), Product Lifecycle Management (PLM), Supply Chain Management (SCM) or Laboratory Information Management Systems (LIMS), Wonderware Enterprise Integrator helps users manage abnormal situations like interrupted connections or loss of data by automatic store and forward; it also allows users to resend or adjust transactions based on a full detailed message history.

Wonderware Enterprise Integrator is capable of providing these extensive integration capabilities because of its support for B2MML message definitions based upon ISA-S95 standards and its flexible message delivery capabilities including web services, file drop, FTP, MSMQ, XML, HTTP, and SOAP, and a message repository using Microsoft SQL Server.

While most enterprise integration projects require connections to specific systems, Wonderware Enterprise Integrator accomplishes this through reusable plug-ins. These plug-ins are developed according to the needs of a specific integration scenario, decoupling Wonderware Enterprise Integrator’s core functionality of message handling and delivery from necessary transformations that may vary depending on the business system or Wonderware MES application configuration. The plug-ins can also be developed to provide default connectivity to business applications such as SAP, Microsoft Dynamics or Oracle. Once a plug-in is created, it can be reused with other installations of Wonderware Enterprise Integrator to support company standards within multi-site integration rollouts.

During the Manufacturing Operations Management Solutions session at the Wonderware Conference 2015, presented by Schneider Electric’s Chris Azer and Tom Troy, they explained that a key underlying concept of Manufacturing Operations Management is the combination of traditional MES functions for production and material management with quality and asset management into a Manufacturing IT platform. Providing the ability to connect these functions is a key facet of what Wonderware Enterprise Integrator is all about.

Azer and Troy explained that it is possible to connect any business system or third party automation application on the shop floor using Wonderware Enterprise Integrator so that one consistent approach for plant-to-enterprise integration is adopted. This approach eliminates isolated silos of information and high maintenance point-to-point integrations, while also reducing IT maintenance costs, they said.