DTM Simplifies Motor Starter Setup

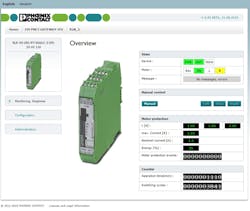

Phoenix Contact is shipping bus-capable motor starters based on the tried and tested CONTACTRON hybrid technology, which uses FDT/DTM for operation and parameterization. In Ethernet-based bus systems, all relevant functions are additionally available via web interface. The use of additional web technologies in the DTM offers new graphical possibilities, resulting in a uniform user interface for the two environments. The web interface facilitates the drives' startup even without a PLC or control system; the only software tool required is a web browser.

The network is set up by means of gateways that support the following fieldbuses: PROFINET, PROFIBUS, Ethernet/IP, CANOpen, DeviceNet, Modbus/TCP, and INTERBUS Inline. The system enables the user to transfer relevant process data such as motor current, number of cycles, and motor protection status to the control system.

Phoenix Contact's line of CONTACTRON hybrid motor starters offers a wide selection of products for controlling and monitoring electric drives. It covers motors operating at up to 500 VAC at nominal motor currents of 0.075 through 7 A. The integrated emergency stop function was designed for SIL 3/PLe safety; the devices comply with the ATEX directive.

Options for connecting the devices include both screw terminal blocks and PT terminal blocks. The devices have all relevant approvals for worldwide use.

For more information, please visit:

https://www.phoenixcontact.com/online/portal/us?1dmy&urile=wcm%3apath%3a/usen/web/main/products/technology_pages/subcategory_pages/CONTACTRON_Hybrid_Motorstarter_Technology/30c25406-fb10-4f69-bbc0-6ab7f13aecef