Gateway Provides a Bridge Between Measurement and Maintenance

For many automation systems, direct intervention into device parameterization and online diagnostics while the plant’s operating brings significant challenges with respect to cost and effort. In the past, maintenance technicians had to apply for a work permit/allowance for activities in hazardous or difficult access areas. The same was true for the on-site connection with an intelligent sensor or actuator in the field.

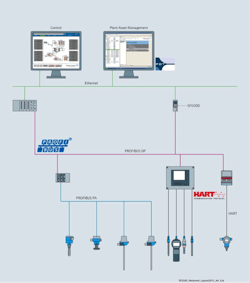

The Fieldgate - SFG500 PROFIBUS gateway from Endress + Hauser can simplify maintenance. The SFG500 is a system component of Endress + Hauser, which acts as a gateway interface between PROFIBUS DP, PROFIBUS PA and HART communication protocols, even in the hazardous areas. It can be linked through the embedded web server to any existing PROFIBUS automation topology; even during plant operation; quickly and without parameterization in operation. This retrofit property is one reason that many users rely on the SFG500 of Endress + Hauser. On the one hand, the gateway represents a parallel data transfer to the control system installed. On the other hand, it provides physical separation from the PLC infrastructure without any changes, giving the supervising on-site staff more flexible application scenarios.

In short, the SFG500 gateway is the key for Plant Asset Management. The central element is a PC that runs an FDT-based software tool, FieldCare. This will allow maintenance staff permission to perform the relevant tasks remotely with this maintenance station via FieldCare. Whether users are commissioning a new radar-field device, a Coriolis mass flow meter, or a positioner, the FieldCare project contains all the relevant field device data. Each SFG500 physically connects a complete PROFIBUS segment with help from FDT Technology. The associated nested communication allows access via Remote I / O`s and linking devices with HART and PROFIBUS PA devices.

Modern infrastructure (FieldCare PAM, SFG500, Remote I / O) Benefits:

- Devices can be used from any manufacturer, thanks to DTM (FDT) and iDTM (EDDL) support. - Cross-vendor operation with a single maintenance tool

- Equipment parameter changes are now also possible from a local maintenance station. - Significant time savings during commissioning and diagnostics

- Graphical representations of measurement signals for radar and ultrasonic field devices are now available without restriction.

- Partial Stroke Tests and Advanced Performance analyses can be performed - This commissioning function allows a full measurement performance test.

- Device diagnostics can be viewed through the SFG500 web interface or delivered as an e-mail. Here the SFG500 provides detailed information about the cause of the failure and associated remedial actions to solve the failure. This goes far beyond the scope of diagnosis as defined by NE107.

- With the FDT based FieldCare tool, DTMs and iDTMs are used for detailed analysis and solving problems.

For more information, please visit: www.endress.com/SFG500.