FIPA’s Custom Material Handling Solutions Improve Reliability & Decrease Cycle Time in Challenging Applications

FIPA Inc., a leading manufacturer of advanced vacuum technology, gripper systems, air nippers, tube lifters, and End-of-Arm-Tooling (EOAT), recently developed a custom material handling solution that both improved reliability and decreased cycle time for one of STVision GmbH’s more challenging automated vision systems.

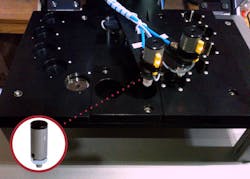

STVision specializes in developing industrial automatic inspection systems for the semiconductor production, automotive, medical, precision metal foil, and watch industries, but struggled to find a reliable solution capable of individually lifting magnetic coded disks from a storage stack and transferring them to a testing site due to their magnetic properties and extremely low profile.

“Prior to partnering with FIPA, we tried utilizing vacuum cups and magnetic grippers, but the former wouldn’t reliably lift individual disks, and the latter would lift several disks at once due to its high performance permanent magnet, so both purported solutions failed, which led to costly interruptions in the automated testing process,” said Dr. Bernd Sommer, general manager, STVision.

In response, FIPA combined one of its high quality vacuum suction cups with one of its vacuum operated lifting cylinders especially designed to stack and unstack thin and fragile products to develop a custom material handling solution capable of reliably lifting, transporting, and precisely placing single 50mm-diameter disks in less than three seconds.

“The material handling solution that we developed for STVision’s automated coded disk testing system not only solved their problem, but allowed them to provide their customer with extremely reliable performance and the ability to achieve higher production volumes, which can increase profitability,” said Rainer Mehrer, president of FIPA. “Solving such challenging design issues and delivering such positive results is the core of FIPA’s business, and a skill that we’re very proud of, as is reflected by our new brand mission and positioning statement: challenge accepted.”

Available in four standard models with lift lengths of 17, 25, 30, and 40mm, FIPA’s vacuum operated lifting cylinders are available with lifting forces spanning 3N to 50N, which makes them ideally suited for stacking and unstacking a wide variety of products ranging from the thin and fragile (e.g., veneers, cards, and signs) to the heavy and tough (e.g., metal sheets), in addition to a variety of pick and place applications. FIPA vacuum lifting cylinders feature anti-twist piston rods and a robust, HART-COAT-treated aluminum housing, are suitable for short cycle times, and are also available in custom lift lengths and low-noise versions. Operating temperatures for the series span 41°F to 176°F.

>>For more information on this product, click here.