Universal Modbus DTM Standardizes Communications

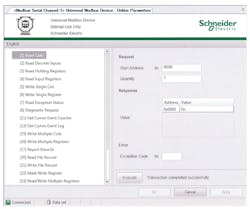

Schneider Electric has developed an FDT2 version of its Modbus Universal DTM. This DTM helps test any Modbus device during development. It provides an easy way to verify a device implementation in an early stage of the development phase. The DTM allows the user to send Modbus commands to a device and provides the corresponding response data. It can communicate with devices connected on Modbus serial line or Modbus TCP. The list below shows all the standard Modbus services which can be executed by the DTM as well as available proprietary services. All the services can be performed cyclically within user-defined periods of up to 10.0 milliseconds.

Standard Supported Modbus Services:

- 01 - 0x01 Read Coils

- 02 - 0x02 Read Inputs

- 03 - 0x03 Read Holding Registers

- 04 - 0x04 Read Input Register

- 05 - 0x05 Write Single Coil

- 06 - 0x06 Write Single Register

- 07 - 0x07 read Exception Status (Serial Line only)

- 08 - 0x08 Diagnostics (max. response data length = 2 bytes)

- 11 - 0x0B Get Comm Event Counter

- 12 - 0x0C Get Comm Event Log (Serial Line only)

- 15 - 0x0F Write Multiple Coils

- 16 - 0x10 Write Multiple registers

- 17 - 0x11 Report Server ID (Serial Line only)

- 20 - 0x14 Read File Record

- 21 - 0x15 Write File Record

- 22 - 0x16 Mask Write Register

- 23 - 0x17 Read/Write Multiple registers

- 24 - 0x18 Read FIFO Queue

- 43 - 0x2B Encapsulated Interface Transport

- 43 - 0x2B / 0x0E Read Device Identification

Support of Confirmed/Unconfirmed Proprietary Request

For specific applications, the FDT2 Universal Modbus Device DTM supports the creation and transmission of proprietary requests. These requests can be either sent as unconfirmed requests (no Modbus response) or as confirmed requests with a private Modbus response.

The Universal Modbus FDT2 Device DTM can be used in any standard FDT2 Frame Application either with an FDT 1.2 Modbus Communication DTM or with an FDT2 Modbus Communication DTM.

FDT Group members can get this FDT2 Modbus Test DTM free from Schneider Electric for their internal tests. For more information, please contact Manfred Brill at [email protected].