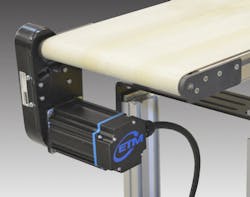

Unique Conveyor Direct Drive Motor Reduces Costs

Using unique next generation motor technology, these motors provide 10 times more continuous torque and at a 5 times wider speed range than conventional AC induction motors. By eliminating the need for a speed gearbox, ETM motors reduce energy usage by 40-70%, eliminate the need to inventory multiple motor and gearbox combinations to address different customer speed and torque specifications, and lessen ongoing maintenance. ETM motor direct drive technology also increases conveyor load capacity across the speed range and lowers drive system costs for conveyor manufacturers. ETM provides optimized drives paired with their motors.

These compact and lightweight motors can provide variable output speeds, output torques from 40 to 1800 in-lb and over 92% operating efficiency. Standard off-the-shelf motors, with or without controllers, are available with 0.5 to 2.2 HP ratings. The company can also produce custom motors outside these ranges to meet special customer needs. In addition to their standard enclosure, the motors are available for wash-down and food processing applications.

ETM direct drive motor technology increases conveyor reliability by eliminating troublesome gearboxes and the associated cost of maintenance and downtime. Since these motors have wide speed and torque ranges, inventories can be significantly reduced.

>> For more information please click here.