Analytical Field Device DTMs Enhance Maintenance

Getting a fast and clear overview of the status of a measurement point using a remote workstation is the basis for effective maintenance. Heartbeat Technology is an Endress+Hauser tool that enables users to monitor and verify measurement points in process automation environments.

Heartbeat devices make it easy to measure performance and identify process trends so users can predict and plan their maintenance tasks. These benefits enable a transition from reactive to proactive maintenance.

Heartbeat Technology is now integrated in FDT/DTMs (Device Type Manager) for Endress+Hauser’s analytical devices. The DTM for the Liquiline transmitter platform has been enhanced with a special maintenance view, which shows all the necessary service information at a glance. Structured with tabs for overview, calibration data, performance calculation and diagnostics give users the desired data without making them search for it in the broad DTM menu structure. Diagnostic and status relevant data are grouped together.

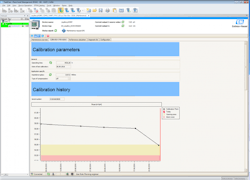

The calibration data tab shows the calibration results in a trend graph. This enables the service personnel to make qualified decisions for preventive maintenance tasks to reduce or combine trips to the field.

With Heartbeat, it is easier to find the optimal balance between process safety and maintenance cost savings. With experience over time, the maintenance strategy can be optimized to best fit the real requirements of the process. Users start with common maintenance intervals and adapt them to the individual requirements. In demanding processes, they can be shortened to ensure a safe operation. In other processes, the interval can be prolonged.

The performance calculation tab presents the results of the optimization, showing availability, mean time between failure and other key performance indicators as basis for the next optimization iteration.

In plants with many measuring points, it is difficult for the maintenance staff to detect the status and condition changes of all installed devices. Therefore, an important advantage of Heartbeat Technology is the integration of device status and secondary variables into the control system. This enables an automatic health monitoring of a huge number of devices.

Despite automatic monitoring and optimized maintenance plans, a regular verification of the measurement point is still required. This verification usually needs a lot of time-consuming paperwork since documentation of the work is essential. Heartbeat devices solve this problem by automatically generating verification reports that contain all module identification and test information. The report states a clear pass or fail result. Personnel does not need to detail interpretations or have special sensor knowledge. The verification procedure can be triggered remotely without process interruption over the fieldbus, and the report can be downloaded and stored with the DTM.