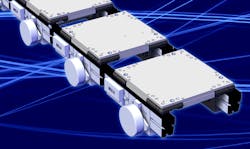

Zero Pressure Accumulation Conveyor

With traditional conveyors there is often backpressure from upstream pallets bumping into each other and stacking up, which can compromise product integrity and quality. In addition, motors running continuously, regardless of actual conveyor requirements, cause extra friction and unnecessary wear and tear on the entire system, including bearings, belts and motors. Continuously running the conveyors also wastes energy. With this conveyor motors run only when a product approaches and has a permissive from downstream, maintaining a gap between products so no back pressure is created. Each accumulation zone is powered by a 24 VDC brushless motor and can handle loads up to 200 lbs. each. The motors are daisy-chained to one another and each uses its own driver card with integrated “zero pressure” logic, including inputs for local sensors. Individually managed accumulation zones make sure that there is always a gap between products. The brushless DC motors are virtually silent and rated for 300,000 hours each.

>>For more information on this product, click here

Glide-Line

www.glide-line.com

215.721.1900