HONEYWELL UNVEILS CLOUD-BASED REMOTE MONITORING SYSTEM FOR THERMAL PROCESSES

Honeywell (NYSE: HON) today announced Honeywell Connected Plant Thermal IQ, a cloud-based remote monitoring system designed to monitor and manage critical thermal process data. This cyber-secure offering is part of Honeywell’s asset performance management (APM) portfolio, which helps customers improve asset performance, which ultimately leads to increased plant uptime.

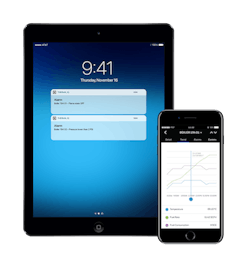

Thermal IQ is a remote monitoring solution for industrial and commercial thermal applications. It securely connects combustion equipment to the cloud, making critical thermal process data available in real time on any smart device. With Thermal IQ, maintenance engineers and plant managers can more effectively monitor and manage their thermal process equipment, minimizing unplanned downtime and maximizing uptime.

“In today’s competitive business climate, it’s vital that production and process systems deliver value by operating in the smartest, most efficient manner possible,” said Tim Lee, vice president and general manager, Honeywell Thermal Solutions. “Thermal IQ does just that, by sending customers actionable information from their combustion equipment which allows them to diagnose potential disruptions ahead of time to facilitate smart, safe operating decisions.”

The product is available to North American customers now, with international deliveries of Thermal IQ expected later in 2018.

Thermal IQ is part of the Honeywell Connected Plant portfolio, which is turning data into insight, from edge to enterprise, to help customers improve their bottom line. Honeywell delivers this through its unmatched domain expertise and advanced analytics capabilities to connect process, assets, people and enterprise to maximize performance.

For more information, click here