Customization Slows Process for Automated Equipment

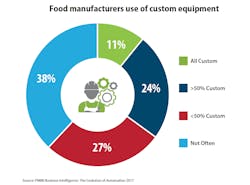

Requests for automated equipment from consumer packaged goods (CPG) companies often become custom orders—62 percent of food manufacturers request customized equipment at some level, according to 2017 Evolution of Automation, a report from PMMI Business Intelligence.

“We get requests daily for customized equipment,” says a managing director for an OEM. “It takes a lot of time to define exactly what the customer’s needs and specifications are.”

Customization is complex, OEMs say. There are different levels of customization for both hardware and software, and it’s possible to get bogged down specifying each individual component, even sensors.

Custom orders increase the time to market for any project. The 58-page report offers comparisons for custom vs. standard equipment offerings and discusses the future of automation, including 3D model-based engineering and digital twins.

For more information, download the executive summary or full report of 2017 Evolution of Automation.