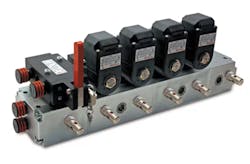

A new redundant valve manifold (RVM) for controlling critical processes brings increased safety and efficiency to Safety Instrumented Systems and other applications where unscheduled shutdowns are unacceptable. The RVM from Norgren is one of the first to offer a two out of three (2oo3) configuration, meaning if one of the three pneumatic logic circuits should malfunction there are two logic circuits still operational, so critical redundancy is maintained.

Norgren, a global supplier of motion and fluid control technologies, has integrated its proven Safety Integrity Level (SIL) certified valves on a single manifold to create the RVM, available in aluminum or stainless steel. The unit eliminates the duplicate piping required to install redundant valve systems. This saves space, simplifies installation and reduces potential leak paths. And, unlike piped systems, the entire valve assembly is SIL approved.

The RVM also features visual indicators of valve position and output status so operators monitoring the equipment can see if they need to schedule service during routine maintenance shutdown. The RVM is also available with a manual or electrical bypass option so valves can be serviced while the assembly remains online. With integral exhaust guards to prevent particle ingress and a temperature range from -55°C to 90°C, (-67°F to 194°F) the RVM is an excellent choice for refineries, chemical plants, off-shore rigs or any process where valve malfunction cannot be tolerated.

>>For more information on this product, click here