Companies are looking for ways to reduce the cost of compliance, improve the safety of people, products and processes, and surpass corporate goals around sustainability. Recent Aberdeen research provides a roadmap for success, based on the best practices adopted by more than 175 executives to effectively manage the above challenges.

Top market pressure

In 2011 the focus on compliance as a driving force behind EH&S programs has only increased. This year, 85 percent of surveyed organizations chose compliance as a top market pressure, followed by the risk of an adverse event as a distant second, at 45 percent. Indeed, as new regulations evolve, internal and external stakeholders are increasingly putting their attention on sustainable business, and the need to stay in compliance with these regulations is at top of mind for these companies.

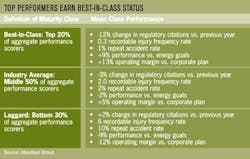

There are four key performance indicators (KPI) criteria to distinguish the Best-in-Class organizations from Industry Average and Laggard organizations, as defined by Aberdeen. It is important to note that, by definition, Best-in-Class companies are not just good in one area, but instead are able to effectively manage performance in all four: compliance, safety, energy efficiency, and profitability. This means that the top companies are not only able to create a safer and more compliant working environment for their employees, but are also able to gain a competitive edge in the marketplace by possessing higher operational efficiencies at a reduced overall cost.

Underperforming companies are performing well-behind the Best-in-Class in these metrics, and need to take some strong steps to improve their EH&S programs. Such companies should use this research to understand the steps taken by their Best-in-Class peers and implement those practices in their strategic, as well as tactical, actions to realize improved performance. This research can also be utilized to gain sponsorship from the senior management on the value of implementing the capabilities and technologies highlighted in the rest of the report.

Strategic actions

From a strategies perspective, there are two major themes that emerge from executing a successful EH&S program: improve visibility into operations and building compliance into business processes. The most prevalent of these strategies is building compliance into business processes.

Depending on the area of the business under consideration, this can take on many different forms. When it comes to health and safety in operations, this can include: machine operators and maintenance personnel recording near misses/hits, verifying and documenting lockouts/tagouts and confined-space work, and taking a behavior-based approach to safety. When it comes to product development or the supply chain, building in compliance means ensuring that all stakeholders are using up-to-date product and material information, and verifying design decisions against regulatory requirements.

Coupled with this, Best-in-Class companies also understand the importance of improving visibility within operations, and having the capabilities in place to provide visibility to critical EH&S data to the right people, at the right time, and in the right form.

Nuris Ismail, [email protected], is senior research associate and Matthew Littlefield, [email protected], is senior research analyst at Aberdeen Group in Boston. Their latest research is “Compliance Management in Environment, Health and Safety.”

About the Author

Leaders relevant to this article: