But these are mostly extensions of old stuff, reincarnations of tired concepts that can’t generate real growth and just won’t cut it much longer. It’s not that they can’t afford to do something different—most of them have lots of cash, but they are too conservative to do much beyond short-term extrapolations.

You know what Steve Jobs said, “If it’s good, don’t do it —it’s got to be insanely great!” Perhaps only a gutsy CEO with good market insights can make that kind of call. And how many of those are there in the automation business?

The problem is that, without top-level direction, marketing and engineering budgets can only produce new products that are mostly tweaks and extensions to support current product lines. No one has the gumption to do anything that is “insanely great”—functionality that customers need and want, but no one really supplies because it’s too different. Automation is overdue for a revolution, an inflection point.

Decentralized control

Here’s some food for thought: How effectively would the Internet operate if it ran primarily with centralized intelligence? Well, that’s how process controls and automation systems operate today. The inventor of the PLC, Dick Morley, has been preaching peer-to-peer decentralized control systems for two decades, but no one has really run with it. Their excuse is that industrial customers are too conservative. I suppose that’s true, but no one is demonstrating the practical advantages of real alternatives in large systems. The automation majors are too chicken to invest significantly to prove the point. They’re waiting for some gutsy little company to show that it has overwhelming benefits.

In my role as a technology futurist, I’m often asked to review new tech, which gives me a lead-in to new ideas and growth arenas. Let me share some of the excitement I felt as the keynote speaker at a recent conference organized by Automation Control Products, a decade old startup based in Alpharetta, Georgia, the developer of ThinManager software.

The conference was in Las Vegas, at The Venetian. There were about one hundred attendees, all from industrial end-user companies like Potash, Frito Lay, Kroger and Nestle USA, plus control systems integrators and industrial software companies; no airlines or banks or commercial users. These were all practical automation engineers and technicians who had oodles of experience with running process plants, automation factories and giant packaging lines. It turns out that most of them had already used ACP ThinManager software since its first development about a decade ago. Did it have bugs? Sure, but many of the users there had helped to fix them, because they really needed the functionality and there were no real alternatives. And they were there because they wanted more and better.

You don’t need “fat” PCs all over the factory or plant to do that. The computers are all “thin” and accessible via the network. Anyone with ThinManager software has access to literally thousands or even millions of control and display variables. For engineers who move around and want to connect whenever and wherever, they can use multiple monitors located anywhere on the network, or even an iPad or iPhone with the ThinManager app.

These are the seeds of truly distributed control systems. Today’s centralized controls and displays will give way to peer-to-peer I/O and the other ingredients of decentralized automation systems. This will happen when the engineers who are making things work at the grass roots levels see the overwhelming benefits and participate in the revolution.

Meantime, most top managers in the automation world are too busy looking into their rear-view mirrors to see the future coming at them. Fast.

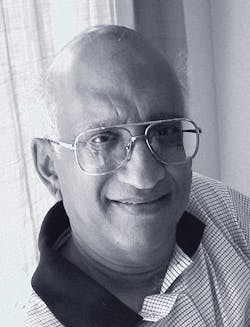

>> Jim Pinto is a technology futurist, international speaker and automation industry commentator. You can email him at [email protected] or review his prognostications and predictions on his website: www.jimpinto.com.

About the Author

Leaders relevant to this article: