GE (www.ge.com) released a report and announced a number of service products to promote its vision of the technology--the Industrial Internet. Automation World's David Greenfield provides an excellent analysis of the announcement (see www.automationworld.com/can-industrial-internet-unleash-next-industrial-revolution).

I'd like to take this to another level within the automation and control space. There are many technologies that had to come together to bring us to this point. The system begins with smarter sensors, networking (short and long distance), communication protocols, databases and analytics. Of course, GE has products and expertise with these. So, too, do several competitors. GE's advantage is that it is using all of its technologies internally to prove them out. The divisions will apparently now begin to market them more broadly.

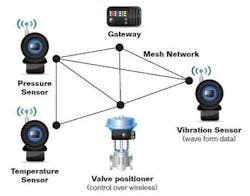

One communication technology where this plays out in our space is short-range Wireless Sensor Networks. GE has been the strongest proponent of the ISA100.11a standard for wireless sensor networks promulgated by the International Society of Automation (www.isa.org). Things have been quiet for some time on that front as the competing WirelessHart technology has begun to advance in the market. There has been a flurry of argumentation recently on the committee. Independent sources have told me that any thoughts of convergence between the two systems is likely dead. At least as far as the ISA100 committee is concerned.

Sources have told me that GE had been working on the technology that has become ISA100 for quite some time. Now that you see the grand announcement from no less than CEO Jeff Immelt, you can see why GE has a hard time backing down from its stance on that committee. Looks like it has staked a lot on going down this path.

Looks like all you engineers out there are going to have to live with a choice. Or maybe the gateway suppliers will step up and let you mix the two networks in different areas of the plant. At any rate, the picture is getting clearer.

And we are closer to ubiquitous information that will help us run our plants more effectively. That is a good thing.

About the Author

Gary Mintchell

Editor in Chief

Leaders relevant to this article: