Some of you may know that I moonlight as the guitar player in a hard-edged blues/rock band. Playing at the various clubs around town, I run into my share of “dirty power” typically caused by poor wiring leading to ground loops. As a guitarist, these problems can wreak aural havoc with amount of buzz and hum issuing from my amp. However, the problems I face as a guitarist are nothing compared to what can happen when these same power issues impact critical automated equipment.

Dealing with these power concerns has been an ongoing issue for engineers forever; and though these same power issues affect industrial data communications, this problem is not addressed as often. Considering that data communications are becoming ever more integral to production operations, I figured now is as good a time as any to review the issue of surge suppression versus isolation.

Because serial data communications lines can carry damaging electrical transients caused by anything from ground loops to lightning strikes, the question for engineers becomes where do you deploy isolation and where do you use surge suppression for data communication lines? Reviewing information from B&B Electronics (a designer and manufacturer of industrial connectivity and communication devices), helped bring some clarity to the decision-making process around this choice.

Let’s start with B&B Electronics’ review of power basics: A surge suppressor directs high voltage transients—such as those arising from lightning strikes—safely to ground. But if the ground line rises, as it does in ground loop situations, isolation is the preferred method. Isolators stop transients by converting data signals to either pulses of light or an electrical field, then back again. Data passes through, but transients don’t. However, a very powerful transient can still damage the isolator.

As a result, you’ll probably find it necessary to use both suppression and isolation. Where you deploy surge suppression and where you deploy isolation will be a function of the specific application.

To help further clarify your surge suppression and isolation options, here’s a brief rundown on the basics of each based on information gathered from B&B Electronics:

• Surge suppressors come in many different shapes, sizes and ratings, ranging from the simple power strip standing between your computer and your power source, to large capacity DIN rail mounted modules. A suppressor suppresses a surge and dissipates it before it reaches and destroys critical components. To help understand how a suppressor works, imagine a large dam taking the brunt of a large wave and slowly letting it out through the spillway. That’s essentially the concept of how a suppressor operates. Suppressors are available to protect power lines and data lines, but are most effective when used as a first line of defense on power supply lines.

• Mechanical isolation (transformer) plays a significant role in isolating sensitive equipment. Unlike suppressors that stop surges of high voltage, transformers block the dc component of the surge. Transformers work effectively in isolating systems that use modulated signals, such as phone systems and Ethernet communications because of their tightly defined frequency ranges. Additionally, transformer isolation is essential in virtually all ac power transmissions, stepping the voltage down to an appropriate level.

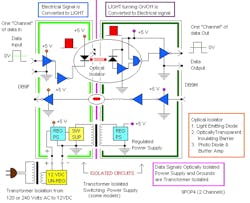

• Optical isolation (see accompanying graphic) operates by bringing data into an isolation module and converting it into a light signal using a light emitting diode (LED). This signal is picked up by a photo diode receptor within the same isolation module and converted back into its original form. The physical gap between the light transmitter and receptor provide the needed isolation from transient current.

• Triple isolation basically extends isolation to each data port as well as the power supply, thereby ensuring a completely isolated system. Inside each module, circuitry is separated, with no electrical connections between any two ports of the board. However, this method requires a second, isolated power supply to power the circuitry of each port of the board.

According to B&B Electronics, triple isolation is the highest level of protection for your equipment because it cuts off all available pathways for transient surges and ground loops. B&B Electronics advises that most equipment that employs triple isolation should be able to handle volts in the 2,000 – 3,000 range.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: