At the inaugural Smart Fields Summit last month in Houston, “big data” was hardly mentioned without speakers also expressing their dislike for the term “big data.”

“I don’t like the term big data,” says Troy Christensen, exploration and production (E&P) backbone data director for BP. “If you’re in the data, it’s very voluminous. There’s massive amounts of data to process.” The question is, how do you find the important bits of data that actually let you change behavior?

Christensen has worked several years to get data gathered from around BP to work together. Integrating processes throughout the organization required figuring out how to make the data talk with each other, which has been no easy task. The challenge has been that each function throughout the company performed and gathered data well, “but wasn’t speaking the same language even within the same company,” he says.

Despite some frustrations with data, it’s finally gaining the attention it needs to make a difference in oil and gas, signaling a major shift in how digital oil fields handle the huge amounts of information coming out of sensors and other instruments. “As long as I’ve been in this industry, I’ve never been as excited as I am about the change that data is going to make to our lives in the next five to 10 years,” Christensen says.

“I’m delighted that we’re now beginning to talk about data as an asset,” adds Colin Frost, CEO at Energy IQ Consulting. “The words ‘smart fields’ and ‘digital oil fields’ is a big reason for that. It really deserves to be treated as an asset.”

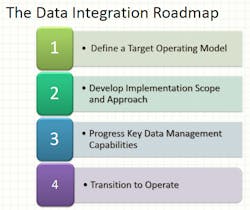

To make the best use of data, Christensen and Frost worked together to pull disparate data together, creating a data integration roadmap for BP that’s involved defining a target operating model, developing the implementation scope and approach, progressing key data management capabilities, and transitioning to operate.

They were trying to pull together data across four different major business processes and three different business functions, Christensen says, first breaking the information down into manageable pieces and then assigning those pieces to the processes. “We had to define the scope of what we were asking for, and decide who we were going to ask to manage it,” he adds.

Part of the task has been to standardize the common process requirements at BP. “Most process owners don’t understand what is needed in order to manage their processes,” Christensen says. “We need to make sure that the data they’re using in that process will enable the process to work. All of that has to be defined at a fairly low level so that you can start to build up the rules by which that data gets managed.”

BP is now seven years into the program, and is just now thinking about the tools that they will use to manage the data. “We had no idea what the tools were going to be,” Christensen notes. “We had to get the processes in place first.”

Although data is an “IT thing,” Frost says, the data management needs to be business-led. “Just the word ‘data’ puts people to sleep, especially business people,” he says, noting the need to bring data together and make decisions about it in a high-quality way. “Decisions that are being made are being made quickly, and a lot of them are automated,” he says.

A lot has changed during the time that BP has been working on its data management program, including business priorities, Frost says. “Ten years ago, we would’ve never predicted the way we do business now,” he says. “It’s requiring more data, more quickly.”

Frost described the need to draw parallels with analog wells around the world. Those with similar formations or similar production processes can tell BP a lot about how the current well might behave, for example. “We’re bringing all of this into operations, and it needs to be that we’re living and breathing this stuff,” he adds.

“For most companies, kicking off a data initiative is really about developing foundational data management capabilities (standardization, harmonization, alignment and operations) across respective business lines,” Christensen says. “Unless these core foundational capabilities exist or are developed as part of the program, data programs can’t deliver their full potential.”

About the Author

Aaron Hand

Editor-in-Chief, ProFood World

Leaders relevant to this article: