Emerson Expands Reach in Oil and Gas with Roxar Acquisition

Emerson Electric Co., St. Louis, announced on May 5 that it has acquired Roxar ASA (www.roxar.com), an international technology solutions provider to the upstream oil and gas industry, based in Stavanger, Norway.

The deal creates the world’s first integrated automation solutions company whose products span from subsea oil and gas reservoirs, to platform and floating production, to transmission, and ultimately through refining and production of goods, Emerson said. Roxar becomes part of Emerson Process Management (www.emersonprocess.com), Austin, Texas, adding subsea reservoir management and production optimization for global upstream exploration and production (E&P) customers. Terms of the deal were not disclosed.

Roxar has annual revenue of US$200 million. It has 28 offices in 19 countries with a network of wholly owned offices in Europe, the Americas, Africa, the Commonwealth of Independent States (CIS), Asia Pacific and the Middle East. Roxar’s international customer base includes all of the multinationals, major independents and the majority of national oil companies.

Subsea additions

“This acquisition is strategic to extending our solutions to help E&P owners meet the automation challenges of offshore subsea,” commented Steve Sonnenberg, president of Emerson Process Management. “Roxar’s knowledge, technology and services combine perfectly to expand Emerson’s solutions.”

Emerson Process Management’s PlantWeb digital architecture uses intelligent digital networks to create smart platforms, floating production storage and offloading (FPSO) and on-shore facilities. Roxar’s products and software systems add major subsea capabilities, including smart downhole networks to support E&P owners’ growing need for real-time reservoir production optimization and flow assurance.

“Roxar is the upstream industry’s largest provider of subsea instrumentation—a complement to Emerson’s end-user-voted industry leading instrumentation and valves that power the digital PlantWeb architecture,” added Sonnenberg.

“We are excited to join Emerson and bring together our common drive for innovation, complementary products and customer solutions,” commented Gunnar Hviding, chief executive officer and president of Roxar. “Our mission, now supercharged by this union, continues to be one of effectively solving E&P owner’s reservoir management problems and helping them maximize production.”

Flow knowledge

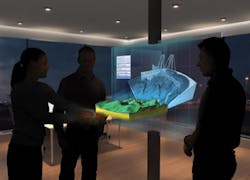

Roxar solutions are based on knowledge of reservoir flow dynamics by the company’s staff of geoscientists, engineers, software developers and computer scientists. The solutions combine real-time data from the company’s multiphase flow instruments, with predictive models from its software to help operators monitor production continuously, observe and control oil and gas fields from remote locations, process large volumes of vital reservoir data quickly and use the most up-to-date field information when making operational decisions.

As Emerson does for topside and on-shore process management, Roxar experts provide consultancy services for entire reservoir management, including topside, subsea and downhole. Roxar solutions allow reservoir operators to make reservoir management and flow assurance decisions with the maximum amount of information. Roxar solutions include Reservoir Interpretation, Reservoir Modeling and Uncertainty Management, Reservoir Simulation, Well and Completion, and Production and Process Management.

Emerson Process Management

www.emersonprocess.com

Roxar ASA

www.roxar.com