Analyze Resource Performance

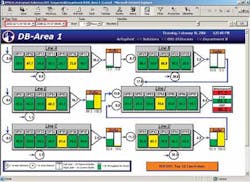

A key component of this application is the introduction of the patent pending Throughput Capability Metric, which uses information captured from the automation layer in the plant to identify and qualify a resource’s current performance against the overall plant Takt Time, a measure used to match the pace of work to the average pace of cust-omer demand. The Throughput Analyzer is designed to help customers identify which resources are constraining the product flow within high volume discrete manufacturing facilities, enabling them to resolve problems immediately and achieve the best possible improvements in plant performance.

The Throughput Analyzer is the first in the company’s line of ActivApplications, a new suite of next-generation applications that draw upon the capabilities of the APMS. The tool is based upon the Toyota Production System, a framework for organizing manufacturing facilities with the goal of eliminating waste, and Eliyahu M. Goldratt’s Theory of Constraints, a body of knowledge on effective management of organizations as systems. The Throughput Analyzer is designed to make it simple for manufacturers to identify those key constraints that most impact the bottom line.