Siemens to Acquire Engineering Software Provider Vistagy

Composite materials, such as carbon fibers, have been finding their way into a growing array of products over the past several years. These materials can now be found in products ranging from sports equipment to kitchen and bath countertops. They are also found in the aerospace industry for uses such as the creation of rotor blades on wind power turbines (due to their low weight and high strength) and in the automotive industry for body panels and braking systems.

The fast-growing use of composite materials is what attracted the attention of Siemens Industry to Vistagy, a Waltham, Mass.-based provider of engineering software for the creation of products incorporating composite materials. The agreement to move forward with Siemens' acquisition of Vistagy was signed in early November, but no terms of the acquisition have been released. The transaction is subject to customary approvals, and is expected to close before the end of 2011. If all goes according to plan, Siemens says it will integrate Vistagy's products, services and support operations into the PLM software business unit of Siemens Industry Automation Division.

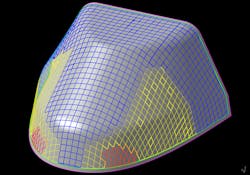

Vistagy's software products include: FiberSIM for designing and manufacturing durable and lightweight composite structures; SyncroFIT for designing and manufacturing complex assemblies and large aerostructures; Quality Planning Environment used in developing plans to assess aerostructure quality; and Seat Design Environment for designing and manufacturing transportation seat systems and interior components.

Siemens has long been affiliated with the automation of production lines for carbon fiber components and claims that, with the acquisition of Vistagy, it will become "the only company worldwide to support the whole value creation for carbon fiber components with its software tools — from product definition and development to manufacturing and service."

The fast-growing use of composite materials is what attracted the attention of Siemens Industry to Vistagy, a Waltham, Mass.-based provider of engineering software for the creation of products incorporating composite materials. The agreement to move forward with Siemens' acquisition of Vistagy was signed in early November, but no terms of the acquisition have been released. The transaction is subject to customary approvals, and is expected to close before the end of 2011. If all goes according to plan, Siemens says it will integrate Vistagy's products, services and support operations into the PLM software business unit of Siemens Industry Automation Division.

Vistagy's software products include: FiberSIM for designing and manufacturing durable and lightweight composite structures; SyncroFIT for designing and manufacturing complex assemblies and large aerostructures; Quality Planning Environment used in developing plans to assess aerostructure quality; and Seat Design Environment for designing and manufacturing transportation seat systems and interior components.

Siemens has long been affiliated with the automation of production lines for carbon fiber components and claims that, with the acquisition of Vistagy, it will become "the only company worldwide to support the whole value creation for carbon fiber components with its software tools — from product definition and development to manufacturing and service."