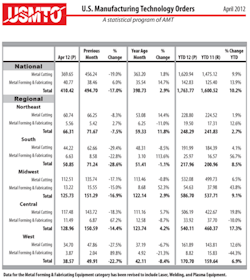

With major media outlets just starting to understand what's driving the U.S. economy, the Association for Manufacturing Technology (AMT, www.amtdwg.org) and the American Machine Tool Distributor's Association (AMTDA, www.amtdwg.org) release the April 2012 economic report showing manufacuturing orders are up by 2.9% compared to April 2011. This manufacturing report provides regional and national U.S. consumption data of domestic and imported machine tools and related equipment. Analysis of machine tool consumption provides a reliable leading economic indicator as manufacturing industries invest in capital metalworking equipment to increase capacity and improve productivity.

These numbers and all data in this report are based on the totals of actual data reported by companies participating in the USMTO program.

“Year-to-date orders of manufacturing technology are up a solid 10% over 2011,” says AMT President Douglas K. Woods. “Rising factory productivity and consistently climbing employment in the industry are indicators that the manufacturing technology sector is still going strong. Things are looking brighter as we get closer to the IMTS 2012 manufacturing show in Chicago.”

A recent column by Alan Beaulieu, president, Institute for Trends Research, for Automation World, states the growing proportion of manufacturing to the GDP:

The chart shows that manufacturing as a percentage of Gross Domestic Product (GDP) has increased from the December 2009 low of 11.0 percent to 12.2 percent today. The change is impressive in that it is occurring despite the loss of some export potential to Europe because of their mild recession and the slower rate of growth in China. The advantages of U.S.-based manufacturing are becoming more evident with both domestic and foreign firms taking advantage of “near-sourcing.” U.S. industrial production is rising, illustrating beyond a doubt that we are in recovery and not a recession/depression. The trajectory is consistent with the forecast we put in place in early 2011.

The USMTO report also reports on a regional basis for five geographic breakdowns of the United States, see below:

Northeast Region

Manufacturing technology orders in the Northeast Region in April totaled $66.31 million, down 7.5% from March’s $71.67 million but up 11.8% when compared with the April 2011 figure. At $248.29 million, 2012 year-to-date is up 2.7% when compared with 2011 at the same time.

Southern Region

Southern Region manufacturing technology orders totaled $50.85 million in April, a 28.6% decrease from the $71.24 million total for March and 1.1% less than the total for April 2011. The year-to-date total of $217.96 million is 8.5% more than the comparable figure for 2011.

About the Author

Grant Gerke

Digital Managing Editor

Leaders relevant to this article: