Dataforth Commits to Production of 5B Signal Conditioning Modules

Despite the decision by National Instruments to "obsolete" 5B modules in September 2012, Dataforth Corporation will continue to manufacture their entire 5B family of signal conditioning products in Tucson, AZ. 5B modules are used today in industrial and commercial markets ranging from power generation, defense and aerospace to the automotive field, alternative energy, medical devices, mining, and optics.

“Our customers can be assured of a solid supply of 5B modules for at least the next 10 years,” says Bill McGovern, National Sales Manager at Dataforth. “5B technology is a viable solution for thousands of users worldwide, and our 5B sales continue to grow year-by-year. For us, therefore, the 5B is nowhere near end-of-life.”

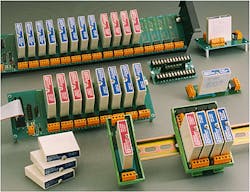

Dataforth’s extensive product line of isolated analog 5B signal conditioners includes 19 family groups and more than 250 different modules. Input modules interface to all types of industrial sensors. The modules filter, isolate, and amplify input signals, then convert them to high-level analog voltage output ready to interface directly to customers’ data acquisition and control systems. Analog inputs include voltage and current in narrow and wide bandwidths, thermocouple, RTD, accelerometer, potentiometer, strain gage, frequency, and 2-wire transmitter. 5B output modules accept high-level analog voltage signals from a host system and provide process current or voltage output to field devices.

The fully encapsulated 5B signal conditioners are all designed for industrial plant environments and are ideal for virtually all temperature, pressure, and flow applications. They are extremely easy to use and simply plug into Dataforth’s extensive offering of single, dual, 8- or 16-channel backpanels.

Key features include:

- ±0.03% Accuracy (Typical)

- 1500Vrms Transformer Isolation & 240Vrms Field-Side Protection

- ANSI/IEEE C37.90.1 Transient Protection

- 4- to 6-Pole Low-pass Filtering

- -40°C to +85°C Operating Temperature

- CSA C/US Certified (Class I, Division 2, Groups A, B, C, D)

- CE and ATEX Compliant

Accessories include DIN rail mounting options, cables, racks, and power supplies. Custom modules are available upon request.

Dataforth Corporation- www.dataforth.com