New Industrial Network Survey Reveals Upgrades Are Needed

A survey of 128 engineering, operations and IT professionals reveals that, when it comes to industrial networking, their number one concern is reliability. In fact, “in unforgiving mission-critical conditions, there is simply zero tolerance for downtime. Engineers need the network to be so reliable that it becomes invisible.”

This is according to a report from St. Louis-based Belden, sponsor of the survey and maker of industrial networking connectivity products. The survey was conducted among AutomationWorld.com readers in July 2012.

When asked if they were confident in the capabilities of their current industrial communications network infrastructure, 74.8 percent of respondents said, “not without modifications or investment.”

Learn More

To learn more about the findings and hear a deeper discussion of industrial Ethernet, listen to the on-demand webinar sponsored by Belden. The event, “Designing Reliable Industrial Ethernet Infrastructures” included a question and answer period at the end.

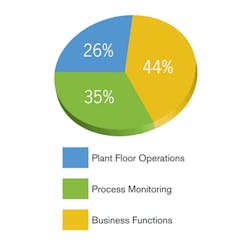

The report says, “Industrial Ethernet is most firmly rooted in initiatives to drive control and automation (86.1 percent) and data acquisition (67.3 percent).” But enterprise mobility is growing as well. Two-thirds of respondents say they are actively using wireless communications in industrial settings, and integrating it with business functions (44 percent), process monitoring (35 percent) and plant floor operations (26 percent).

Least likely to use Ethernet

Also from the report, “Personnel safety and physical security are by far the two least used areas for industrial Ethernet (13.9 percent and 11.9 percent, respectively). Yet overall security, including physical security, was a top concern when respondents were asked about their current industrial network infrastructure, second only to reliability. “These two overlooked areas introduce major vulnerabilities, especially in light of the growing threat of industrial-specific cyber attacks like Stuxnet and Flame,” said the report.

To learn more about the findings and join a deeper discussion of industrial Ethernet, register for the Belden webinar on “Designing Reliable Industrial Ethernet Infrastructures”, which takes live questions Wed., Aug. 15 and then is available on-demand through AutomationWorld.com. Or, visit Belden's blog, which focuses on subject areas that are top of mind for users of mission-critical signal transmission solutions. The topics include the rapidly growing area of end-to-end Ethernet in industrial environments, and security challenges faced in process automation and control systems.