Eplan Acquires Maker of Wire Harness Design Software

Eplan, maker of Electric P8 computer-aided engineering software, has taken over the development and sales rights to Harness Expert, the established 3D/2D software for wire harness engineering made by Linius Technologies. The contract between Linius Technologies and Eplan Software & Service was signed on June 28, 2012.

The acquisition will allow Eplan to offer its customers even more comprehensive support for all aspects of control cabinet design and cable project management. According to an Eplan spokesman, "The strategic purchase of the Harness Expert software will provide considerable potential in the domestic and international markets. It will allow Eplan to tackle new segments of industry, including apparatus engineering, rail and specialist vehicle technology, aviation, telecommunications and medical technology."

In addition, the new software will help ePlan meet the increasing demand from within its own customer base for the implementation of 1:1 connections via wire harnesses, which is the result of an increase in the number of circuit-board based units being used in control cabinets.

"The purchase of the Harness Expert software makes our portfolio broad enough to cover all engineering requirements within the global market. It also gives us a considerable competitive advantage, especially in the international market," said Maximilian Brandl, chairman of the executive board at Eplan Software & Service. He said the company is planning to distribute the software internationally under the name of "Eplan Harness Expert" from autumn 2012.

What is a wire harness?

A wire harness is a bundle of wires which normally have plugs or terminals at the end to create electrical connections to components and devices. It is considered a passive device. By fixing the wires together, e.g. by wrapping tape around, fitting them into protective sleeves or hoses or putting them in cable conduits, the individual wires are fixed in harness form and can be fitted in the same way as a single cable. The wires are also protected from dirt, heat and mechanical strain with a view to securing electrical properties such as insulation and conductivity throughout the service life of the product.

Unlike conventional (sheathed) cable, wire harnesses are developed on a project or application-specific basis depending on the connections required. The benefits of this approach includes optimization of the space and weight within the installation space and ideal conditions for connection requirements and pre-fitting/mass production can be achieved even for small batch sizes.

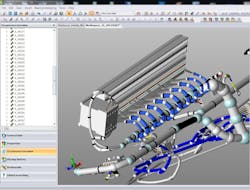

Eplan Electric P8 previously handled the engineering of single wires and sheathed cables in the control cabinet and field components. Now, customers can benefit from this consistent process integration, as all phases of the engineering process are supported, from planning through engineering through to wire harness design and production.

Harness Expert supports all aspects of wire harness engineering. All 2D production documents are produced by the system, which allows comprehensive openness when it comes to the import and export of third-party systems in design, administration and production. Integration between Eplan Electric P8 and Harness Expert provides all relevant wiring information, such as wire specifications, source/target information and bundle and socket assignments. This integrative workflow reduces engineering time and costs.