Product Lifecycle Gets Compliance, CAD and Catalog Enhancements

The category of Product Lifecycle Management has always covered a broad area of automation software technology. Over the past decade, PLM has grown from its core roots in CAD/CAM/CAE software with engineering-to-manufacturing capabilities to encompass the entire product lifecycle from idea creation to product phase out.

An array of recent announcements from Siemens PLM expands the category even further.

Regulatory Compliance

To help OEMs and their supply chain partners more effectively choose materials that comply with regulations impacting the markets in which their end products will be sold, Siemens PLM has increased its Teamcenter software capabilities to better address this issue. According to Siemens PLM, it’s not just that companies have to correctly select compliant materials, but they must also have a sustainability strategy to phase out or replace current components and materials with new “green” ones.

To handle these requirements, new Teamcenter features include:

• Material and substance management;

• Environmental compliance process management;

• Design for the Environment (DfE) framework; and

• Data exchange with sustainability-related applications.

Using these new features, users can trace a substance across a product bill of material definition, control the material makeup of their products and limit the use of hazardous substances. Furthermore, users can determine the effect of a substance regulation on a product early in the lifecycle and understand its impact on their company’s bottom line.

Scroll to the bottom of this article to see a video from Siemens PLM detailing the new Teamcenter sustainability features.

CAD/CAM/CAE

Another component of the Siemens PLM software suite, NX CAD software, has also recently been updated with several customer-driven features. This new version of NX — NX 8.5 — will be released in October 2012 and features:

• New design commands that reportedly shorten design cycle times by up to 30 percent. NX 8.5 also includes new capabilities for feature modeling, sheet metal design, freeform modeling, validation checking and drafting.

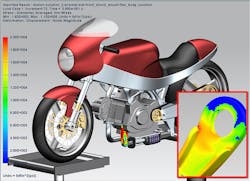

• Simulation enhancements help development teams more efficiently engineer products. For example, new optimization tools such as NX Shape Optimization suggest specific, detailed improvements to an existing design to reduce stress concentrations. NX 8.5 also includes improvements in simulation modeling, structural, thermal, flow, motion and multi-physics analyses.

• NX CMM Inspection Programming has been added to NX 8.5 with measurement results analysis and display inside of NX.

• New cutting tool library and CAM data management capabilities support faster NC programming and make it easier to access and re-use resource information, while ensuring the use of correct data from NC programming through to machining.

Cutting Tool Catalogs

Siemens PLM Software and Sandvik Coromant are working together on an initiative to develop new cutting tool reference standardization for use throughout industry. The initiative addresses three key areas: classification structure, tool attribute definitions, and a standardized approach to 3D model definitions of cutting tool components and their assembly.

The lack of standardization among cutting tool vendors was the primary driver behind Siemens PLM and Sandvik Coromant working together on this initiative. Without any form of standards, it is difficult for manufacturers to access automated cutting tool information to use within their manufacturing planning databases and applications.

A key aspect of the Siemens PLM/Sandvik Coromant initiative is that the two companies adopted and built upon available ISO and STEP standards.

For its manufacturing customers, Siemens PLM Software has also developed a customer tool library mechanism so that it can import and manage standardized cutting tool vendor catalog data, handle the transfer of selected data sets to working tool libraries, and build 3D tool assemblies from component model data.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: