Machine Building: Initiative Wants to Standardize Cutting Tool Vendor Catalogs

Sandvik Coromant, a Fair Lawn, N.J. supplier of cutting tools and tooling systems for the metalworking industry, has teamed up with Siemens PLM Software, Plano, Tex. on an initiative to standardize the structure and content of cutting tool vendor catalogs. The effort promises help manufacturers address the complexity of obtaining cutting tool definitions and data in a useable form, and more efficiently integrate cutting tools into production systems.

Stan Przybylinski, director of research at CIMdata., said, “Although much effort has been put into developing and promoting standards for tooling systems, we see this as the first time that a major tool vendor has joined forces with a major PLM software and manufacturing equipment provider to define a solution that spans the tooling industry and end user requirements. This is a pragmatic approach that builds on the available ISO standard with definitions that will be open to all tool vendors and software providers. Given the substantial customer base of both companies and their connections across the industry, we believe that this initiative will go far in addressing the challenge of standardization in cutting tool information systems.”

Manufacturers with machining equipment can purchase cutting tools from a wide-range of suppliers and they need to use electronic definitions of these tools within their manufacturing planning and shop floor production systems. However, each cutting tool vendor typically has their own approach to classify different types of tools, describing critical tool specifications — such as diameter, lengths, angles — and representing geometric computer-aided design (CAD) models of those tools. This makes it difficult for manufacturers to access cutting tool information in an automated fashion for use within manufacturing planning databases and applications, and forces engineers to manually enter individual data sets from vendor catalogs into their internal systems.

Mike Verkamp, manager of business development for Sandvik Coromant (www.sandvik.coromant.com), said the company "has recognized the tremendous technological development in machining processes, materials and tooling which is driving the need for virtual machining capabilities. Working with data in varying formats can be a challenge, but we expect that this initiative will not only offer manufacturers a standard format for vital cutting tool data, but will simplify their CAM [computer-aided manufacturing] and virtual machining systems, helping them better optimize productivity and profitability.”

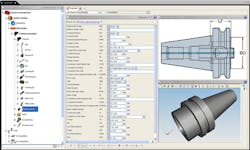

Siemens PLM Software and Sandvik Coromant have defined and developed a new level of standardization that will be openly available for use throughout the industry. The initiative addresses the three key areas of classification structure, tool attribute definitions, and a standardized approach to 3D model definitions of cutting tool components and how they can be assembled. Verkamp says the project will address key needs in virtual machining such as standard tool data format, connectivity to CAM packages, and automatic updates of new data.

The companies have adopted and built upon available ISO and STEP standards. ISO13399 provides a definition for tool attributes and the STEP AP214 standard provides a basis for 3D representation of tool components and automated assembly points. The latter allows end user customers to more easily utilize 3D models of their cutting tool components and assemblies as needed in both NC programming and machining simulation applications, as well is in shop floor systems such as tool pre-setters.

Siemens PLM Software and Sandvik Coromant say they are collaborating with other major cutting tool vendors to share and drive this initiative across the industry. Specifications and methods will be available to all partners as an open standard. Key manufacturers are being invited to advise on the implementation methods as well as to share their specific requirements for access to tool catalog data. Click here for more information Standardized Cutting Tool Catalog Initiative.

Siemens PLM Software has also further developed its Manufacturing Resource Library, which is part of the Teamcenter® portfolio. This will enable the company’s large base of manufacturing customers to import and manage standardized cutting tool vendor catalog data, handle the transfer of selected data sets to working areas within tool libraries, and build 3D tool assemblies from component model data. Key elements of this solution are already being used by existing customers.