Emerson Process Management’s Smart Machinery Health portfolio now provides an integrated protection and prediction solution for critical reciprocating compressors. Common compressor issues can be predicted before they cause a process upset, greatly reducing lost production and repair costs.

Reciprocating compressors are often maintenance-intensive machines at a production facility and are critical to production uptime. With Emerson’s integrated approach for reciprocating assets, rotating and reciprocating machines can now be monitored through one maintenance management system.

Emerson’s reciprocating compressor solution includes standard protection functionality as specified in API (American Petroleum Institute) 670 and API 618, and adds powerful predictive monitoring to identify a user’s most troublesome issues: valves, pressure packing, rider bands, and rod faults. Emerson’s CSI 6500 Machinery Health Monitor with PeakVue technology monitors ultrasonic emissions to determine valve health – reported as the number one maintenance issue by users. Transient monitoring of rod position identifies abnormal or excessive changes in rod position before it impacts pressure packing and monitors vertical rod position to track rider band wear. Advanced asset management capabilities enable users to view rod position via 2D plots, illustrating piston rod dynamic motion that can be viewed live, paused and replayed.

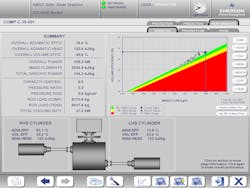

Emerson’s integrated solution also delivers compressor frame vibration shutdown protection as specified by API 618 and piston rod monitoring as specified by API 670. AMS Suite provides additional performance and machine condition information through monitoring parameters such as adiabatic efficiency, volumetric flow, rod tension and rod compression. Combining shutdown protection with predictive diagnostics delivers the information that users need to protect their equipment health while avoiding production downtime.

"With over 25 years of experience in machinery health technologies, we have the tools and expertise to help users both protect their critical equipment and predict failures before they cause major production issues in applications such as midstream LNG, off gas, flare gas, and dirty gas reciprocating compressor processes," said Bjorn Salomon, general manager of Emerson’s Machinery Health Management business. "By taking advantage of our innovative technologies, domain expertise, and service capabilities, our customers gain diagnostic information needed to allow operators and maintenance personnel to confidently act early to maintain equipment health, while ensuring API standards compliance."

>>For more information on this product, click here