Making a showing at Hannover Fair 2013 earlier this month, Lenze focused on the ways it is working more effectively with its OEM customers, showcasing several new products.

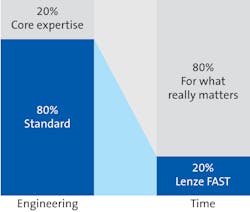

To help machine builders reduce engineering time, the Lenze FAST (Feasibly Active Software Toolbox) product has an application template and ready-made standard software modules. Programmers can use Lenze FAST to cover up to 80 percent of all their software engineering requirements for standardized machine modules quickly and reliably.

The significant reduction in software development time and costs that more and more companies are now demanding can be achieved with standard software. Experience has shown that 80 percent of the software for a new machine can be generated using code developed for previous generations, or which can be provided in the form of ready-made technology modules from system partners like Lenze.

However, for this to work, it must be possible to provide the software with the necessary structure. To simplify this step, Lenze has developed an application template that provides important structures—such as error handling, state machine for switching over machine states, and communication interfaces—and thereby guarantees standardization. The software modules created on the basis of the application template can then be put together like bricks with minimum effort, creating systems that are easier to understand and can be reused.

A second product is the Smart Motor, which combines in a single unit an AC motor and a soft start drive. This offers many advantages, including a reduction in the number of different drive variations by up to 70 percent, convenient operation via RFID from a smartphone, a flexible range of potential applications, and easy handling. Mechanical and plant engineering companies in the field of materials handling technology in particular will enjoy the benefits of this technological quantum leap because it allows mains and starter applications to be carried out considerably more easily with a motor.

About the Author

Gary Mintchell

Editor in Chief

Leaders relevant to this article: