Manufacturing Intelligence from Existing Data

Manufacturing intelligence applications have been in wide distribution for nearly two decades. Like most advanced technologies, the early years for enterprise manufacturing intelligence (EMI) were difficult. Common user complaints about EMI software typically centered on its lack of intuitiveness, integration difficulties and high cost. The difficulties with EMI often weren’t so much an issue with the software itself, but that the supporting technologies needed for EMI to function at its peak simply weren’t well developed enough.

This is no longer the case. With advances in every area relevant to EMI—from field device/machine connection advances to ever-increasing bandwidth capabilities and from database management/connection to cloud computing—the key barriers to effective EMI have largely been removed.

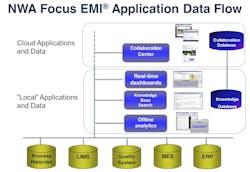

Coming from decades of experience leveraging manufacturing data for statistical process control (SPC), Northwest Analytics has recently launched NWA Focus EMI. Beyond core EMI capabilities such as customizable dashboards tracking specific key performance indicators (KPIs), NWA Focus EMI offers two “accelerating” modules—KnowledgeBase and Collaboration, which are designed to improve a user’s ability to accumulate and disseminate knowledge across the enterprise and collaborate across geographically dispersed manufacturing operations to pinpoint and resolve issues and share best practices.

A key aspect of NWA Focus EMI is that it supports all commercial databases. Northwest Analytics claims its software can connect directly to all existing manufacturing databases, including historians, laboratory information systems (LIMS), manufacturing execution systems (MES) and enterprise resource planning (ERP) software. As a result, NWA Focus EMI does not need to create a separate database to deliver its core EMI capabilities.

The Knowledgebase module of NWA Focus EMI does involve the creation of a new searchable database. “It’s created by collecting events and issue information via points that are identified by analysis and users to capture all relevant information,” says Peter Guilfoyle, vice president of marketing for Northwest Analytics. “The data contained in Knowledgebase is information that’s not already being captured and stored elsewhere.”

The cohort to Knowledgebase is NWA Focus EMI’s other “accelerating” module known as Collaboration. This cloud-based module is used to “quickly mobilize expertise and experience across the enterprise to solve critical production issues.” Asynchronous communication managed by the Collaboration module integrates text, graphics, pictures, documents and video to share important, complex information. The ultimate point of the collaboration is to ensure the right people have the right information and context to solve pressing manufacturing issues.

The Dow Chemical Company is an early adopter of NWA Focus EMI, and already has 14 plants using the software. “We were looking for a better way to retrieve, join and analyze data and turn that information into real knowledge throughout the organization,” said Lloyd Colegrove, director of fundamental problem solving at The Dow Chemical Co. “With its ability to directly access data from multiple databases and apply analytics in real time, NWA EMI Focus is giving us immediate access to critical process information and focuses us on the information and best practices that most influence and improve our production output and quality.”

In addition to Dow Chemical, Guilfoyle notes that Albermarle, a global manufacturer of complex chemicals, is also using NWA Focus EMI in 10 of its 34 plants. He notes that 12 other manufacturers have been using NWA Focus EMI prior to its official launch on May 15, 2013.

Guilfoyle adds that implementation of the software averages only one to three weeks and that ROI is typically achieved in less than six months. This is a direct result of the software leveraging existing databases, eliminating data duplication and its movement to a separate system for analysis.

As part of the launch of NWA Focus EMI, Northwest Analytics announced strategic partnerships with system integrator companies Stone Technologies and Maverick Technologies. Both system integrators can deliver and implement NWA Focus EMI. Stone Technologies and Maverick Technologies are CSIA-certified system integrators.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: