Mitsubishi Electric Automation Creates Online Knowledge Base

Mitsubishi Electric Automation created an online knowledge base to provide automation professionals with quick access to research and troubleshooting information. The knowledge base provides users with access to Mitsubishi Electric Automation technical and product information in one location. It offers a comprehensive compilation of videos, manuals, specifications and guides for installing, configuring and troubleshooting Mitsubishi Electric Automation products.

“Now, engineers, technicians, engineering managers, machine operators and other technical professionals in the automation industry can use this resource to help simplify their jobs,” said Brad Kaufman, Technical Information Development Engineer for Mitsubishi Electric Automation, Inc.

The online resource covers Mitsubishi Electric's comprehensive line of factory automation solutions. Products include programmable automation controllers (PAC), programmable logic controllers (PLC), human machine interfaces (HMI), variable frequency drives (VFD), servo amplifiers and motors, motion controllers, control software, computerized numerical control (CNC), and Robots.

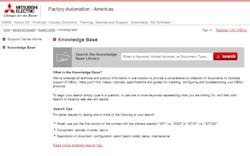

The knowledge base is easy to use. Registered users simply begin a search by typing in a question, or using one or more keywords representing their topic of interest. They can then quickly scan documents for search terms using the quick view feature, or narrow search results with custom filters. There is also advanced search functionality for executing more effective queries.

To register for the knowledge base, visit