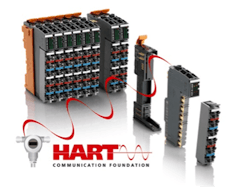

B&R Press Release: B&R adds HART modules to the X20 I/O series

Data transmission, configuration and diagnostics of field devices

B&R now includes an analog HART input module and a HART output module in their successful series of X20 communication modules. These new modules are equipped with two inputs and outputs and use real-time Ethernet POWERLINK to transfer HART data supplied by sensors and actuators directly to the controller. To evaluate the data, the controller forwards information via the process bus to maintenance stations with FDT containers, for example B&R Automation Studio, PACTware or FieldCare.

Controller handles asset monitoring

In the other direction, this type of communication makes it possible to configure the HART devices. This is done with B&R's TCP/IP communication DTM, which scans the network and detects the entire hardware tree, including field devices. The DTM server on the controller operates as a gateway that provides read/write access to all detailed information regarding HART field devices for asset monitoring. Read/Write function blocks support this access during logic processing as well.

One modem per channel ensures more than enough bandwidth

Each channel on B&R HART modules has its own HART modem in order to optimally utilize POWERLINK's high transmission bandwidth. In addition, the comparatively slow HART channels are not encumbered further by multiplexing, as is common in many other systems. HART modules in the X20 series also provide burst mode support, include multidrop functionality and can directly supply up to five devices per channel.

>>For more information on this product, click here