ICP DAS USA, Inc. Reveals the Importance of Ethernet Communication in Industrial Systems

Industrial Ethernet (IE) refers to using standard Ethernet protocols in an industrial environment. IE systems use the same physical layer that already exists in most environments and can easily be expanded upon, reducing the need to add another network. Industrial Ethernet communication opens up a new freedom for application configurations and system design. Ethernet communication enables us to create more efficient and flexible networks. Ethernet networks are everywhere.

Communicating using long cables is a thing of the past. Why go through the trouble of laying new communication cables when there already exists a medium that can more efficiently handle the payload and is already in place? Instead of using repeaters, you can install gateways or converters to expand upon the network.

One of the great benefits of using or extending an existing Ethernet network is that we only need a few Ethernet cables and a few spare ports.

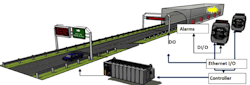

Let’s look at our traffic tunnel monitoring solution using our ET-7000 series modules.

Tunnel safety has been regarded as a key roadway safety issue. The consequences of tunnel accidents tend to be much more serious because of the enclosed space, poor lighting, rapid expansion of heat and smoke, and complicated evacuation procedures. The worst thing is that sometimes the drivers entering the tunnel do not know that an event like an accident has happened inside. The lack of real-time access controls result in difficulty of evacuation and delay of rescue. To help reduce potential accidents - especially for long tunnels, it is critical to have a well- designed emergency warning system that provides real-time monitoring and access control.

The ET-7000 series web based I/O modules launched by ICP DAS have been used in traffic control systems in many countries for lighting controls; so it was very easy to add upon the existing Ethernet network. The Emergency Transmitters equipped with ET-7000 modules are established every 200 feet in these tunnels. At the time an emergency occurs, drivers can press the button of the closest transmitter and the ET-7000 module will receive the message and send the emergency information to the controller in the central control room trough the Ethernet, showing the location of emergency immediately. The central control room can monitor the situation of the tunnel through their system to turn on alarms, close the tunnel and activate warning lights in the tunnel.

Compared to the non-uniformity of physical layers in various fieldbus systems, users have good reasons to be optimistic about the future of Industrial Ethernet. The fact that all upcoming Ethernet-based industrial networks all use the same data transmission technology is a considerable advantage in comparison to the large number of different transmission technologies of the Field Bus. Industrial Ethernet will not immediately replace the conventional Field Bus. Instead it will open new applications and will support the migration towards distributed intelligence in automation.

Modules used in this application include:

ET-7060 – Modbus TCP Data Acquisition Module with 6 Digital Inputs and 6 Relay Digital Outputs

NS-208R- Industrial 8 port Ethernet Switch supports -40 to 85 degrees C

WP-8449-1500- Programmable Automation Controller (PAC) Windows CE5.0 with Indusoft

>> To learn more about the variety of ideas and real projects integrated with ICP DAS hardware, click here