Using Digital Tools to Calm Overstocking Issues

Automation engineers are still grappling with supply chain challenges that emerged during the COVID-19 pandemic. Despite supply lines returning to near-normal conditions, issues like persistent microprocessor shortages and delays in receiving power equipment persist, Control reported.

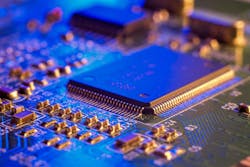

A lack of diversification in chip sources, especially for analog cards used in PLCs and drives, resulted in long lead times during the pandemic, with chips being diverted to industries like medical and automotive. To mitigate future crises, suppliers are increasingly diversifying their component sources and enhancing domestic production. This shift, while slow, is improving lead times and bringing stability to the automation industry.

In response to past shortages, suppliers and customers have adopted new strategies, including overstocking to prevent future disruptions. Engineers are now more adept at digitalization, relying on downloadable software and virtualized services when hardware components are delayed. Virtual training programs have expanded, offering flexibility in education and equipment management.

Read more in the full article from Control, an Automation World partner publication.