Interconnect Wire and Insulation Sleeving for Fuel Cells

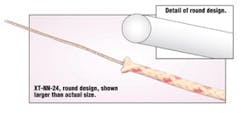

This series of electrical conductor comes in multiple shapes, diameters and insulations. Omega N wire features low electrical resistance at high temperature (up to 1200 degrees Celsius), nickel, stainless and platinum based alloys with an increased surface area and low thermal expansion. Available as single or dual interconnect wire, the XTW-XT version provides 3000 volt High Pot performance testing capabilities. The XTW-XT design is a combination of Omega’s wrapping and over braiding insulation capabilities.

Omega Engineering, Inc. - www.omega.com