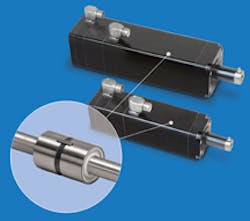

Roller-Screw Option Provides Forces Up to 3,300 lbs for Rod-Style Actuator

The Tolomatic IMA incorporates a hollow core rotor and skewed motor windings into its unique servomotor design for an extremely compact package with increased dynamic performance and service life compared to traditional rod-style actuators. The IMA’s unique integrated motor design is well suited for applications such as pressing, clamping, valve control, spot welding and volumetric filling.

"With the addition of the roller-screw option, the service life of the IMA increases by about ten times or more in high-force applications," says Aaron Dietrich, electric product manager, Tolomatic. "In fact, in an IMA 44, the estimated life of the roller-screw is about ten million inches of travel at a mean force of 2,000 pounds. The standard ball screw on the IMA offers better efficiency and economy, but the roller screw option offers higher force, better accuracy and longer service life in high-force applications."

The hollow core rotor design allows the nut of the screw to pass inside the rotor to provide a very compact package. "This can decrease overall actuator length by as much as 18 inches compared to standard actuators due to the elimination of a separate motor, motor mount and gearbox. In addition, the skewed stator windings minimize the cogging of the motor to provide smoother, more efficient motion and improved force repeatability," says Dietrich. The compact footprint and efficient operation of the IMA, combined with the flexibility of control from an electric actuator, makes the IMA a powerful and viable alternative for replacing fluid power cylinders, he says.

The Tolomatic IMA with the new roller-screw option can exert a force of up to 3,300 pounds and move a top speed of about 12 inches per second. The IMA is available with a choice of motor voltages in any incremental stroke length from 6 inches to18 inches. Built with Tolomatic’s Endurance Technology features for maximum durability and extended service life, the IMA has a patent-pending lead-screw lubrication system that allows easy re-lubrication without disassembly. Tolomatic’s sizing and selection software makes selecting an IMA easy. All orders are built-to-order and shipped with Tolomatic’s industry leading five-day delivery.

Tolomatic - www.tolomatic.com