New Push-In Terminal Blocks Technology

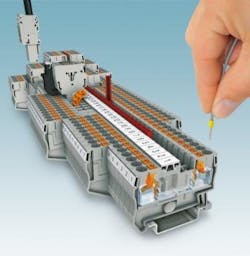

The modular PIT terminal blocks are easy to operate and reduce fatigue. They are ideal for installations with limited space or hard-to-access wiring.

Available in a 2.5 mm2 cross section, the PIT series accepts ferrules between 22 AWG and 14 AWG. The orange actuation button opens the spring to the maximum wiring space of 14 AWG, resulting in fast, easy-to-access wiring and touch-proof safety. The universal button is compatible with any type of tool, even a pen.

The PIT series features approximately 100 part numbers, including feed-through, multi-level function, component and pluggable terminal blocks. As part of the CLIPLINE Complete system, PIT terminals are compatible with standardized push-in bridging, marking and testing accessories for all connection technologies, providing maximum flexibility.

Phoenix Contact - www.phoenixcontact.com/usa_home.htm