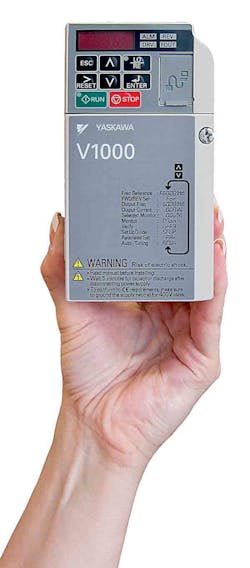

Small, Precision AC Drives

The V1000 can be stacked side-by-side, due to its improved heat-sink technology. The EN954-1 Safety Category 3 safety input to disconnect the motor at the first sign of trouble is standard. “We engineered the V1000 to be smaller, and to be more precise to eek out every bit of production from conveyors to food and beverage machines. It uses less energy, is quieter, and its removable control terminal block speeds installation,” says Todd Ammerman, product manager at the vendor.Yaskawa Electric America www.yaskawa.com800.YASKAWA