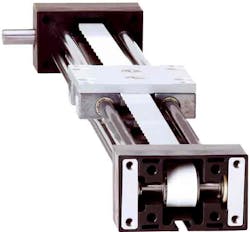

Tooth-belted Linear Drive

DryLin ZLW is well-suited for quickly positioning small loads and can be employed in a number of industries, from packaging to medical technology to food and beverage. DryLin ZLW is available in two configurations: ZLW 01, for zero maintenance, absolutely no external lubrication and a lightweight, cost-effective design; and ZLW 02, designed for applications requiring high speeds. A compact miniature version of DryLin ZLW 01, which only weighs 2 pounds per every 3 feet, is also available. DryLin ZLW 01 is equipped entirely with plain plastic bearings. In addition to the iglide J sliding elements, iglide L250 radial bearings and iglide J thrust washers are used in the pulley mechanism in the end blocks. The design eliminates the need for any oil or grease, as all iglide plastics self-lubricate with a dry lubricant. DryLin ZLW 02 is designed for high-speed applications, up to 20 feet per second. Igus Inc.www.igus.com888.803.1895