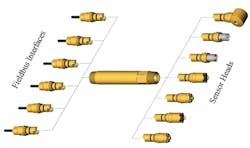

Modular Sensor System

These applications can now be accomplished with PLCs and PCs because DataStick is designed to deliver 24-bit resolution analog data directly over industrial networks, including DeviceNet, Profibus, Modbus, Rockwell DF-1, USB, RS-232 and RS-485, to measure pH, ORP, DO, ozone, conductivity, suspended solids or resistivity. In addition, temperature is measured with all sensors. This analog data quality is equal to or better than most DCSs and process instruments deliver, says the vendor. The DataStick system can be remotely calibrated, configured and diagnosed with any computer, HMI or PLC through a single network cable. The modular DataStick system consists of three parts: The DataStick sensor body is common to all applications and accepts DataStick sensor heads and DataStick network interfaces; the hot-swappable DataStick sensor heads contain the sensor, 24-bit A/D converter and a temperature sensor; the DataStick Network Interface Modules provide network interfaces to popular industrial fieldbuses.