GE Intelligent Platforms, a unit of GE Enterprise Solutions, continues its expansion from discrete into process control by integrating its recent acquisitions by releasing its latest version of Proficy Process Systems – Version 1.6.This version adds support of the PAC8000 process controllers and the PACSystems redundant Rx3i controllers.

These controllers include extended operating range from –40°C to +70°C, ISA Level G3 corrosion, 30G shock and 5G vibration withstand, and can operate in Class 1, Division 2 and Zone 2 hazarduse areas. They can pass Hart information from smart field devices to a computer running device asset management software.

“GE Fanuc continues to provide advanced technology platforms that give our customers the freedom and flexibility to choose their visualization technology – iFIX or CIMPLICITY, and their controller platform – PAC8000 or PACSystems,” said Kam Yuen, GE Fanuc Intelligent Platforms’ Product Manager for Proficy Process Systems. “ This flexibility is very attractive to companies in Oil & Gas, Water / Wastewater, Power & Utilities, Mining, Ethanol, Food & Beverage, Boilers, Data Centers and Chemicals.

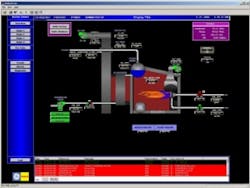

Included with Proficy Process Systems 1.6 is the new Proficy Alarm Viewer that provides advanced alarm line formatting, filtering, and sorting capabilities. It also has an audible alarms capability that annunciates alarms based on the users configured rules. Proficy Process Systems 1.6 also includes new process control function blocks, enhanced visualization faceplates with new look and feel, and new ease-of-use features that enhance the overall usability of the system.

About the Author

Gary Mintchell

Editor in Chief

Leaders relevant to this article: