Thermal Imaging Instead of Thermocouples

Feb. 6, 2012

2 min read

Given that proper maintenance is one of the most important safety-related factors in processing operations, investment in technologies to improve detection of wear and potential breakdown of critical vessels is not difficult to justify.

To improve vessel fault detection, Land Instruments International Ltd., a unit of Ametek Inc., has developed a new monitoring system for critical vessels that uses thermal imaging cameras rather than thermocouples. The cameras reportedly provide a higher measurement density than thermocouple-based systems as they measure surface temperature once every 16 cm2, as compared with one measurement every 250 cm2 in typical thermocouple systems. This higher level of measurement in more locations is said to enable earlier detection of vessel refractory wear or breakdown.

The measurements are taken by harsh-environment, industrial cameras placed in select areas to permit viewing of all parts of the vessel, including the cone and dome sections. Each camera records more than 110,000 individual measurements for detection of even slight degradations.

The system is designed for use in gasifiers as well as vessels in petrochemical refining, power generation, chemical and coal processing, waste management, and fertilizer and plastics production.

Measurements from all cameras are reported using graphical software that signals an alarm if a potential breakout is detected. The software also compiles temperature trends to support statistical analysis of refractory wear. An integrated Web interface allows visualization of current vessel conditions from all plant locations.

From an operations standpoint the system has zero impact on production as it can be installed and maintained without shutting down the process.

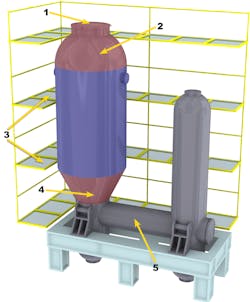

In the accompanying image, a typical installation of Land Instruments Critical Vessel Monitoring System includes (1) one camera monitoring top surface, (2) four cameras monitoring critical dome section, (3) four cameras per floor, and (4) four cameras for the cone section. Additional measurements can be taken on the transfer line (5).

About the Author

David Greenfield, editor in chief

Editor in Chief

David Greenfield joined Automation World in June 2011. Bringing a wealth of industry knowledge and media experience to his position, David’s contributions can be found in AW’s print and online editions and custom projects. Earlier in his career, David was Editorial Director of Design News at UBM Electronics, and prior to joining UBM, he was Editorial Director of Control Engineering at Reed Business Information, where he also worked on Manufacturing Business Technology as Publisher.

Sign up for our eNewsletters

Get the latest news and updates