Materials, Energy Costs Threaten Privately Held Manufacturers

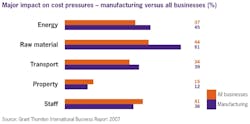

Privately held manufacturing companies see raw materials and energy costs as the biggest threats to their business, according to a recently released study from Grant Thornton International, a United Kingdom-based global accounting and consulting firm. Globally, 61 percent of surveyed businesses reported being most concerned about raw materials costs and 45 percent cited energy costs. Turkish manufacturing businesses are the most concerned about energy costs in the next 12 months with 82 percent of respondents expecting these to have a major impact on cost pressures. Despite being a major oil producing country, 61 percent of manufacturers in Mexico cite energy costs as a concern. Australia and Brazil, also energy producing countries, are least concerned about energy costs, with 20 percent and 23 percent expecting them to have a major impact. “The management of energy consumption is key to tackling global warming —reduction in costs is the result,” observes Alex MacBeath, Grant Thornton’s global head of Privately Held Business Services. “When we asked manufacturers what they were doing, almost two-thirds reported taking measures to reduce their energy consumption. They reported installing energy saving lighting, motion detectors, insulation and measures to ensure that IT (information technology) equipment is turned off while not in use, to cut down on usage and costs. Over half of responding manufacturing businesses are investing in energy saving plant and machinery.” Globalization threat Globalization is perceived as a threat to some manufacturing businesses. According to the report, manufacturers in Thailand, Australia and New Zealand see globalization as a threat rather than an opportunity. This indicates increasing concerns about greater competition from Asian manufacturers. Not surprisingly, Asian manufacturers are among the most positive in regard to globalization. Malaysia and India head the list of those responding forcefully to the need to compete in the international manufacturing market. It is interesting to note that while mainland China has established itself as a highly competitive manufacturing base, a significant proportion of mainland Chinese manufacturers regard globalization as more of a threat. “Rapid growth in China is proving both a blessing and curse for business in Australia and New Zealand,” observes Robert Quant, partner at Grant Thornton Australia. “Increased demand has led to higher production in the Australian resources sector, fueling the mining boom and strong economic growth. However, Australian manufacturers are having difficulties competing with China’s ability to produce low-cost goods and are being constrained by shortages in skilled labor and the lowest unemployment levels for decades.”Grant Thornton Internationalwww.gti.org