Manufacturing Information Systems: ISA88/95-Based Functional Definition

July 8, 2007

4 min read

These

functions range from the receipt of raw material to the shipping of

finished goods, from production itself to equipment maintenance,

through inventory movements and material quality tests, and from

customer order lines to work dispatching. That’s not to mention the

control of manufacturing operations themselves. These functions fall

under different responsibilities, though they must operate

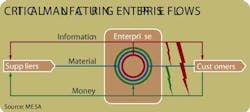

collaboratively under effective business management directions.The role of information in a manufacturing company is summarized in the illustration. Consider the three main flows crossing an enterprise system—material, money and information. It is easy to understand the specific importance of this information. Material flow constrains money flow, that is, no payment until delivery. Information flow constraints material flow, that is, there is no delivery until shipment documentation is issued. Information flow constrains money flow, because there is no payment until an invoice is issued.A manufacturing information system is therefore an enabler to reaching higher levels of financial performance. Conversely, a poorly designed and tuned information system definitely hurts the plant’s ability to serve the company’s goal of sustaining and increasing profits.Invisible infrastructureToday’s ideal information systems are flexible, invisible information infrastructures that constantly adapt themselves to the actual resources, products, business and decision processes of the enterprise. They are no longer a constraint to developing a differentiating, winning strategy. Attaining the ideal information system implies reaching the highest level of maturity in development and maintenance, minimizing the effort needed to:Dompierre-les-Tilleuls , France . The author represents MESA International, www.mesa.org.

- add, cancel, extend or improve existing capabilities in real time

- capture existing constraints impacting the bottom line as user requirements

- implement and support continuously improving manufacturing and business processes, and

- benefit from the technology as it is available, when and where appropriate.

- Top-down, looped global life-cycle (able to work bottom up)

- Master project providing resources for actual instance projects

- Split between functional and technical core system

- Shared resource model

- Pragmatic development through actual or pilot instance projects

- Extensive capture of the user needs through highly structured framework

- Implicit to Explicit Knowledge conversion and management supporting a continuous improvement process.

About the Author

Sign up for our eNewsletters

Get the latest news and updates

Leaders relevant to this article: