RFID Ramping Up in Manufacturing

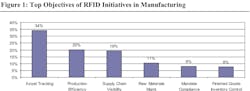

The use of radio frequency identification (RFID) technology is primed for rapid growth among manufacturers, according to a recent report from Aberdeen Group Inc., a Boston-based analyst company. “Penetration of RFID into the manufacturing sector is only 3 or 4 percent today; but, growth is strong—over 112 percent in 2007—and the average manufacturer’s RFID budget will grow from $50,000 to $75,000 per year in 2006 to $100,000 to $200,000 in 2007,” says the report. Titled “Can RFID Deliver the Goods? The Manufacturer’s Visibility into Supply and Demand,” the report is based on a survey of more than 150 manufacturers that are using or planning to adopt RFID technology. In total, Aberdeen Group says that during the last 12 months, it has surveyed more than 600 companies that are using RFID. During that time, the percentage of companies adopting RFID primarily to satisfy a government or customer mandate has fallen by half, says the report. Today, more RFID initiatives begin with other goals in mind, and manufacturers are leading the way, with just 8 percent of projects being compliance driven, the report adds. “Asset tracking” was the top objective reported by manufacturers, at 34 percent, followed by “production efficiency” and “supply chain visibility” at 20 percent and 19 percent respectively (See figure). “Early adopters of RFID in aerospace, automotive, pharmaceutical, paper, electronics and heavy industrial manufacturing are already leveraging [RFID] technology to drive out waste, enable just-in-time delivery of finished goods, and realize continuous improvement throughout the production process,” says the Aberdeen Group report.Aberdeen Group Inc.www.aberdeen.com