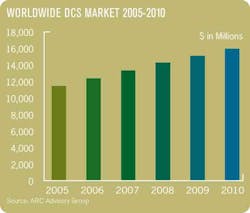

Distributed Control Systems See Strong Growth

“It’s really a perfect storm when it comes to DCS market growth,” says Larry O’Brien, an ARC research director and principal author of the report, titled “Distributed Control System (DCS) Worldwide Outlook.” “Growth continues to be driven by buoyant capital spending and large infrastructural projects in Asia, Eastern Europe, the Middle East, and Latin America. These large grassroots undertakings are complemented by significant investment in the modernization of outdated control systems in the developed markets of North America, Western Europe, and Japan.

“At the same time, we are seeing a shift in spending toward the oil and gas, refining, petrochemical, power generation and other traditional heavy process industries at a level that we have not seen in many years. Higher energy prices and continued demand for energy and power are all contributing to greater spending on automation,” O’Brien continues.

Asia still leads DCS growth for all worldwide regions, and this will not change for at least the next five years, barring any unforeseen political events or overheating of the Chinese economy, according to the study. The dearth of large capital projects and grassroots construction remains the primary reason for this growth, with investment in manufacturing in developing Asian nations far outpacing the already high gross domestic product (GDP) growth that is occurring.

Investment in Asia is also quite high for large infrastructural projects such as power generation, steel mills, paper mills, cement plants and water treatment plants. Investment in other traditional heavy process industries, such as oil and gas production, transportation and refining is also high, ARC says. From a regional perspective, China leads growth in all of Asia, with India also contributing a great deal and at an accelerating rate. In China, however, the growth is unparalleled, and the very latest and most advanced technologies and products are commonly specified for projects.

Both China and India are increasing their focus on manufacturing for export, in addition to developing infrastructure, investing in basic industries, and training personnel to operate plants. China could well become the single largest geographic market for automation in less than 20 years, leading with new grassroots projects for automation, new systems installed, and the addition of manufacturing and energy capacity, the study predicts.